Custom NdFeB for Industrial Equipment

Welcome to our factory’s custom NdFeB for Automotive services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards. You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Submit Your Requirements

Our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

Of course! You are always welcome to visit us. Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. We have a friendly and professional team ready to assist you throughout your visit to make sure you have a great experience.

We are a factory! Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. When you order neodymium magnets from us, you work directly with our factory. This means there are no middlemen, which helps save costs, reduce risks, and ensure a safer and more efficient process for you.

Of course! To save your valuable time and ensure the sample matches your product perfectly, we kindly ask you to provide the specifications, drawings, or a sample of your product. Once we have this information, we will produce and send you the sample. We also allow mixed samples.

Our factory has a professional design team and advanced production equipment, which helps us keep costs low and provide you with high-quality magnets at very competitive prices.

First, decide the shape and size of the magnets that best suit your application. Then, visit our webpages “Customized NdFeB Magnets” and “Customized NdFeB Magnets according to Characteristics” to determine the material and grade of the magnets you need.

The next step is to go to the Quotation Request page and fill out the form with details about the magnets and the quantity you require. After clicking the “Submit” button, we will receive your request and provide you with a price quotation.

You can also contact us directly by sending your specifications and drawings.

General manager: Annie Wu

Tel: +86 18926353690

E-mail: [email protected]

It usually takes 1-3 working days. At the same time, we will assign dedicated technical staff and a business manager to your project to provide full support, including technical assistance and follow-up services.

We’re sorry, but from our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

It usually takes 2-3 weeks. If a mold needs to be made, it may take longer. For large quantity orders, such as ten thousand pieces, it may take 3-5 weeks.

Custom NdFeB Magnets for Industrial Equipment: Everything You Need to Know

Neodymium magnets (NdFeB) are among the strongest permanent magnets available today, making them a cornerstone for industrial applications. These magnets are known for their exceptional magnetic strength, versatility, and ability to meet diverse industrial needs. Whether it’s powering motors, enabling magnetic separation, or supporting critical equipment in high-precision industries, NdFeB magnets are indispensable.This article is a comprehensive guide to understanding custom NdFeB magnets and how they are tailored for industrial equipment. By the end, you’ll know why custom neodymium magnets are vital, their applications, and how they can be designed to meet your specific needs.

1. What Are NdFeB Magnets and Why Are They Important?

NdFeB magnets, also known as neodymium magnets, are rare-earth magnets made from neodymium, iron, and boron. These magnets are celebrated for their high magnetic strength and are widely used across industries.NdFeB magnets belong to the strongest permanent magnet family and are anisotropic, meaning their magnetic properties are directionally dependent. This makes them ideal for applications requiring strong magnetic fields in specific orientations.

Key Features of NdFeB Magnets:

- High Magnetic Strength: Up to 10 times stronger than conventional magnets.

- Versatility: Suitable for industrial and commercial applications.

- Compact Size: Delivers high performance in smaller sizes.

2. How Are Neodymium Magnets Made?

Neodymium magnets are made using a process called sintering, where powdered neodymium-iron-boron is compacted and heated to form a solid structure. This process ensures that the magnets are anisotropic, allowing for precise magnetic alignment.

The Steps Involved:

- Mixing the Alloy: Neodymium, iron, and boron powders are combined in specific ratios.

- Pressing and Sintering: The mixture is pressed into shape and heated to form a rigid structure.

- Magnetization: The sintered magnets are exposed to a strong magnetic field to achieve their magnetic properties.

This meticulous process ensures the high magnetic properties and durability of neodymium magnets.

3. What Makes Custom NdFeB Magnets Unique?

Custom NdFeB magnets are tailored to meet the specific needs of industrial applications. Unlike standard magnets, custom options allow for adjustments in shape and size, coatings, magnetic strength, and temperature resistance.

Why Choose Customization?

- Specific Applications: Tailored magnets meet unique operational requirements.

- Improved Performance: Custom designs optimize magnetic force for specific uses.

- Durability: Coatings and plating enhance resistance to corrosion and wear.

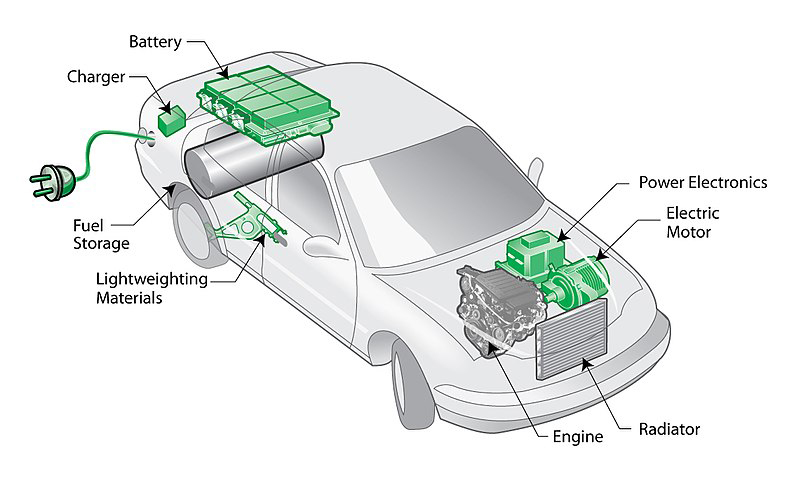

4. Applications of Custom Neodymium Magnets in Industrial Equipment

Custom NdFeB magnets are essential in various industrial sectors, offering magnetic solutions for multiple applications.

Common Uses:

- Motors: NdFeB magnets power high-performance motors in industrial machinery.

- Magnetic Separation: Used in separating ferrous materials from other substances.

- Sensors and Assemblies: Precision equipment relies on the magnetic properties of custom NdFeB magnets.

5. What Are the Benefits of Custom Rare-Earth Magnets?

Custom rare-earth magnets, including NdFeB magnets, offer several advantages:

- Enhanced Magnetic Properties: Tailored to achieve specific magnetic strengths and orientations.

- Corrosion Resistance: Protective coatings like nickel prevent degradation in harsh environments.

- Versatility: Available in different grades, shapes, and sizes to suit diverse applications.

6. Understanding Magnetic Strength and Grades of Neodymium Magnets

The magnetic strength of neodymium magnets depends on their grade, such as N35, N42, and N52. Higher grades offer stronger magnetic fields and are suitable for demanding applications.

Factors Affecting Magnetic Strength:

- Maximum Energy Product: Determines the magnet’s ability to store energy.

- Operating Temperature: Magnets like N52 can perform efficiently under specific conditions.

- Shape and Size: Custom magnets can be designed to maximize magnetic force.

7. Coatings and Plating Options for NdFeB Magnets

Coatings and plating are critical for protecting NdFeB magnets from corrosion and wear.

Common Coating Options:

| Coating Type | Benefits |

| Nickel Plating | Durable and corrosion-resistant. |

| Epoxy Coating | Provides an extra layer of protection. |

| Zinc Coating | Affordable and effective. |

Proper coatings ensure that custom neodymium magnets perform reliably in harsh industrial environments.

8. Factors to Consider When Designing Custom NdFeB Magnets

When creating custom magnets, consider the following:

- Magnet Shape and Size: Ensure compatibility with the application.

- Magnetic Properties: Optimize for specific industrial machinery.

- Coating Options: Choose protective layers based on environmental conditions.

9. Resistance to Corrosion and Demagnetization

NdFeB magnets are known for their high magnetic strength but can be vulnerable to corrosion. Custom designs often include coatings to address this issue.Additionally, NdFeB magnets offer excellent resistance to demagnetization, ensuring long-term performance in demanding applications.

10. Why Collaborate with Magnet Experts for Your Custom Solutions?

When designing custom NdFeB magnets, working with experienced professionals can make a significant difference. Magnet experts help optimize performance and ensure that your magnets meet specific application requirements.

Benefits of Collaboration:

- Tailored Solutions: Experts design magnets to suit your needs.

- Quality Assurance: High standards in magnet manufacturing.

- Comprehensive Support: From design to implementation.

Key Takeaways

To summarize, custom NdFeB magnets are indispensable for industrial equipment due to their:

- Exceptional magnetic strength and versatility.

- Tailored designs to meet specific needs.

- Durability enhanced by coatings like nickel or epoxy.

- Wide range of applications, from motors to sensors.

- Resistance to corrosion and demagnetization.

By understanding the unique properties and applications of custom neodymium magnets, you can make informed decisions for your industrial projects.For more information or to request custom solutions, contact our magnet experts. They’ll help you design the best magnet for your needs!

YLSRE is a factory specializing in the production of high-performance neodymium magnets(NdFeB ) for various industries.

More

Need A Quote?

Submit your drawing

Get a free sample

We will respond within 8H of receiving your message.

Industry News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.