Types of Neodymium Magnet Coatings: Protecting the World’s Strongest Magnets

The Best Ways to Keep Super Strong Magnets Safe: All About Coatings!

Table of Contents

Why Do Magnets Need a Coat?

Think of a shiny, new magnet like a shiny, new apple. If you leave the apple out, it turns brown, right? Magnets can do something like that too! They can get rusty. This is called corrosion.

Corrosion is bad for magnets. It makes them:

- Weaker

- Break easily

- Not work right

We don’t want that! We want our magnets to last a long, long time. That is because many things that we use, have magnets. Magnets are in:

- Mobile Devices

- Audio Equipment

- and even Data Storage!

That’s why we use coatings! A magnet coating is like a raincoat for the magnet. It keeps bad stuff away.

What Kind of Bad Stuff?

- Water: Rain, sweat, even the air can have water in it!

- Air (Oxygen): The air we breathe can make magnets rusty.

- Chemicals: Some things we clean with can hurt magnets.

- Saltwater: Salt is very bad for magnets. It makes them rust super-fast. If it is for a specialized use case, like magnets applications, you need a coating that can resist saltwater!.

Bare neodymium magnets, the strong ones, can lose 90% of their magnetic force in just 100 hours in a salty spray! Imagine a factory near the ocean. Their magnets could be ruined in days without a good coating.

What Materials are Neodymium

Neodymium-iron-boron, is a rare earth material. The main material of neodymium magnets is neodymium-iron-boron.

| Material | Description |

|---|---|

| Neodymium (Nd) | Rare earth element that provides the strong magnetic properties. |

| Iron (Fe) | Provides the structure. |

| Boron (B) | A small amount to help everything stick together. |

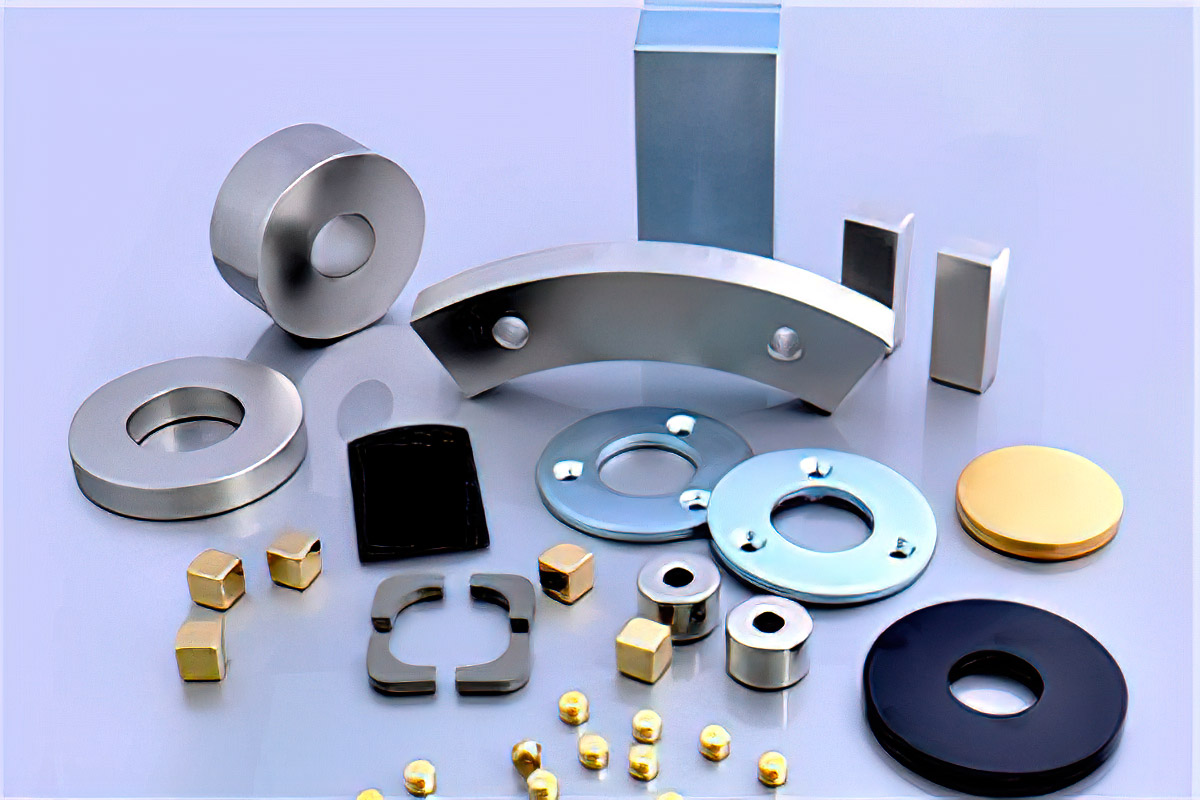

What are the Types of Magnet Coatings?

There are many coatings! Here are some of the most popular, with Magnet Coating options:

1. Nickel (Ni-Cu-Ni)

This is like a magnet’s best friend! It has three layers:

- Nickel

- Copper

- Nickel (again!)

It’s like a sandwich! The copper is in the middle.

Why is it good?

- Strong: It’s tough!

- Shiny: It looks nice.

- Lasts Long: It can handle a lot.

It’s like the all-around good coating, we use a lot of Nickel for magnets in automotive!

How Good Is It?

It can last over 500 hours in a salty spray test! That’s like leaving it in salty water for almost a month! Where do we use it This is put on a lot of speaker magnets in your consumer electronics.

2. Zinc

Zinc is like the budget-friendly coating.

Why is it good?

- Cheap: It doesn’t cost much.

- Good for the Earth: It’s better for the planet than some other coatings.

Why is it not as good?

- Not as Strong: It can get scratched easier.

How Good Is It?

It lasts about 96-120 hours in a salty spray test. That’s still pretty good! Where Do We Use It? Zinc works well in Electric Vehicles, and batteries in automotive manufacturing.

3. Epoxy Resin

This is like a super-tough raincoat!

Why is it good?

- Stops Almost Everything: Water, chemicals… nothing gets through!

- Safe for Electricity: It doesn’t let electricity flow.

- It can be very good for magnets for medical use.

Why is it not as good?

- Thick: It makes the magnet a little bigger.

How Good Is It?

It can last over 1,000 hours in strong chemicals! That’s amazing! Where do we use it We put Epoxy Resin on a lot of marine equipment, and underwater servo motor magnet.

4. Multi-Layer (Like Nickel + Epoxy)

Multi-Layer is what you put when you absolutely need it to last!

This is like wearing two raincoats! One for strength, one for everything else.

Why is it good?

- The Best of Both Worlds: You get the good parts of both coatings!

How Good Is It?

It can last over 10 years in a place like an ocean wind turbine! Where do we use it For very important things, Permanent Magnet Synchronous Generatort use multi-layer coatings.

5. Parylene

This is a special, thin coating.

This helps with humidity resistance.

Why is it good?

- Super Thin: It’s almost like it’s not even there!

- Safe for People: It can even be used inside the body.

How Good Is It?

It can handle 100% humidity, no problem! Where Do We Use It? For things that need very small tolerances, like in Aerospace Engines!

How to Pick the Right Coating

It’s like choosing the right shoes!

- If you’re going to the beach, you wear sandals.

- If you’re going hiking, The magnets in ADAS also need coatings.

- If you’re going to a party, you wear nice shoes.

It’s the same with magnets! We use a lot of magnets in home, like having a speaker. Here are some questions to ask:

- Where will the magnet be used?

- Inside? Outside? In water?

- Will it get bumped or scratched?

- Will things rub against it?

- How much can you spend?

- Some coatings cost more.

| If you need… | Then pick… | Because… |

|---|---|---|

| Something cheap | Zinc | It’s the most budget-friendly. |

| Something strong | Nickel (Ni-Cu-Ni) | It’s tough and lasts a long time. |

| To stop chemicals | Epoxy Resin | It’s like a super-strong shield! |

| The very best protection | Multi-Layer (Ni + Epoxy) | It’s like two coats of armor! |

| Something very thin | Parylene | It’s almost invisible, keeping your magnetic modules small. |

What about Coatings for Other Things?

Gold magnetic

Gold magnetic is sometimes used as a coating for magnetic jewelry, but that is mostly for looks!

PTFE Coating

PTFE Coating are coated with polytetrafluoroethylene, which is a synthetic coating, kind of like Teflon Coating.

Why Pick Us to Make Your Magnets?

There are many applications of magnets, and we have many options, including customized NdFeB magnets, here at our NdFeB magnets factory.

We are the best! Here’s why:

- We Know Everything About Magnets: We’ve been making them for a long time. We have a lot of experience and good equipment.

- We Make Exactly What You Need: Do you need a special size or shape? No problem! Do you need a magnetic sheet? We can do that.

- Our Magnets are the BEST: We check every single one to make sure it’s perfect.

- We Only Use The Best Stuff

- We have all the Best Coatings

- We are Good at Customer Service

- We offer a range of magnet grade for all our customers.

Talk to our magnet experts! They can help you pick the perfect coating.

How to Take Care of Your Coated Magnets

Even with a good coating, you need to be careful!

- Don’t Drop Them: Magnets can break!

- Don’t Get Them Too Hot: Heat can make magnets weaker.

- Keep Them Away From Other Magnets: They can stick together really hard!

- We specialize in neodymium ball magnets, talk to us if you want to magnet fish.

Other Important Words

Here are some big words, but we’ll explain them simply:

- Corrosion Resistance: How well a coating stops rust.

- Adhesion Strength: How well the coating sticks to the magnet.

- Thermal Stability: How well the coating works when it gets hot or cold.

- Nickel Plating: Putting a layer of nickel on the magnet.

- Zinc Coating: Putting a layer of zinc on the magnet.

- Epoxy Resin Coating: Putting a layer of thick, strong plastic on the magnet.

- Electroplating: Using electricity to put a coating on the magnet.

- Oxidation: A fancy word for rust.

- Intrinsic Coercive Force (Hci): How strong the magnet is.

- Salt Spray Testing: A test to see how well a coating stops rust in salty water.

- Multi-layer Coatings: Using more than one kind of coating.

- Passivation: Making the magnet less likely to rust.

- Industrial Applications, like in Industrial Motors.

- Pinhole Defects: Tiny holes in the coating that can let rust start.

- Coating Uniformity: Making sure the coating is the same thickness all over.

- We make custom neodymium magnets, including magnetic systems.

Frequently Asked Questions

Can a Bad Magnet Be Fixed?

What About Saltwater?

Do You Give Out Samples?

Conclusion

When selecting an appropriate NdFeB, consider the correct material, like N52, N48, or N45, as well a durable magnet coating, and make sure to talk to us, the NdFeB magnets factory.

Coatings are super important for neodymium magnets. They keep these strong magnets working great for a long, long time. We are the experts in magnet coatings! We can help you pick the perfect one. We do it all, whether you require customized ndfeb for electronics, or NdFeB for the automotive industry, such as for powertrain systems. Contact us today!

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.