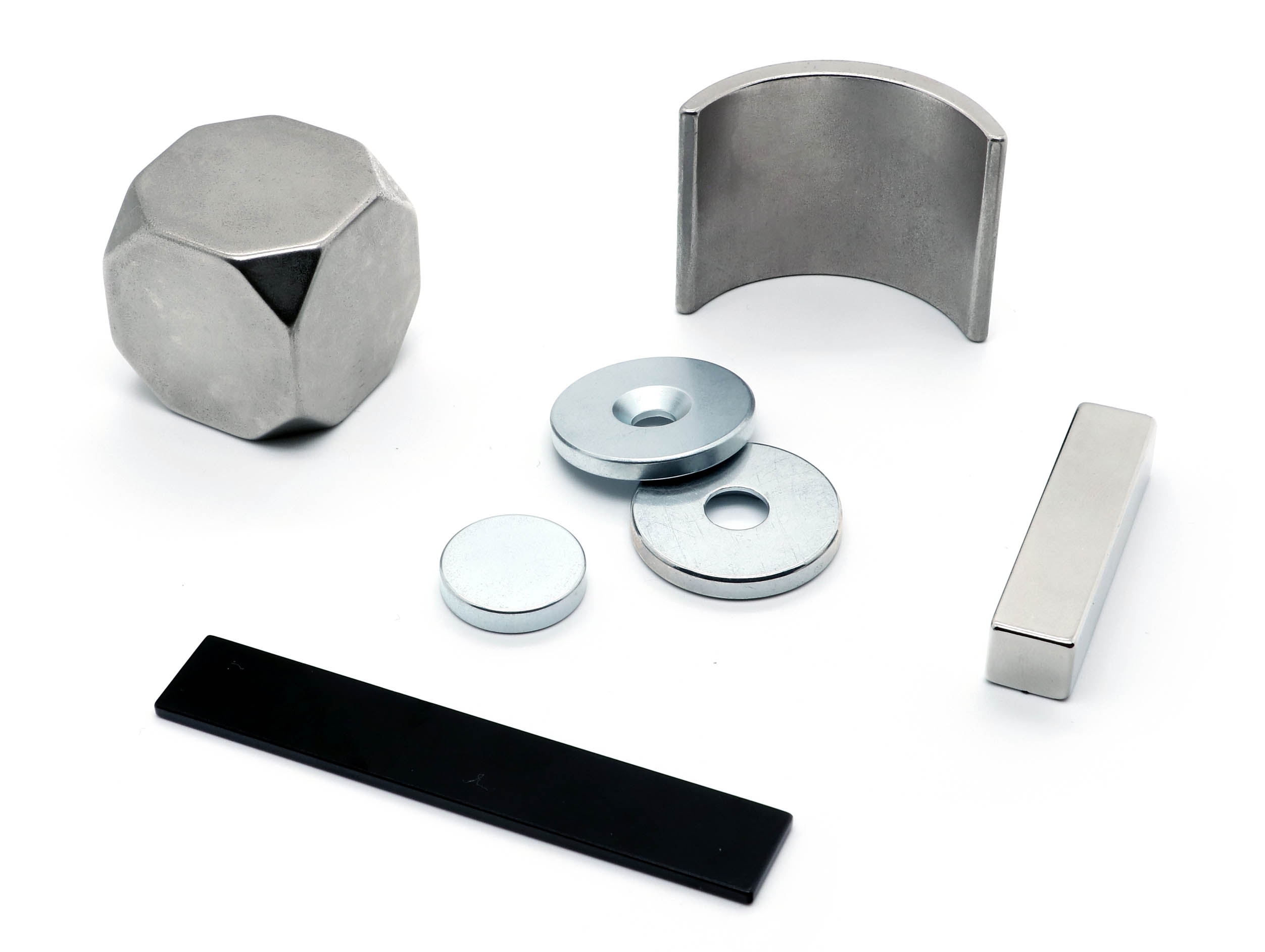

regular surface treatment of neodymium magnets

Making Neodymium Magnets Last Long: A Simple Guide

Table of Contents

Why Do Magnets Need a Special Coat?

NdFeB magnets are like cookies. If you leave them out, they can get bad.

- Water can make them rusty.

- Air can make them weak.

- Bumps can make them break.

So, we put a special coat on them. It is like a raincoat for the magnet! We call this surface treatment. This aligns with our dedication, highlighted at neodymium magnets factory, to delivering top-quality products.

Different Coats for Different Jobs

There are many kinds of coats. Here are some important ones:

| Coat Name | What It’s Good For | How Long It Keeps Magnets Safe | Example |

|---|---|---|---|

| Nickel-Copper-Nickel | Keeps away rust | Keeps magnets like new for over 720 hours in salty air! | Car parts that need to be strong in the rain |

| Zinc-Nickel | Super strong against rust | Keeps magnets safe for over 1,200 hours! | Magnets on windmills near the sea |

| Epoxy | Good with chemicals | Can handle things that are very sour or very soapy! | in doctors‘ machines, like MRIs. |

| Parylene | Very, very thin | Stops almost all water from getting in! | Magnets in spaceships! |

| Phosphating | Helps glue stick better | Makes it harder for the coat to peel off | Magnets in big machines that shake a lot |

: Simple introduction to explain concepts. : Analogy to explain. : Definition of key term.

1. Nickel-Copper-Nickel Coat

This is like a sandwich! It has three layers:

- Nickel

- Copper

- Nickel

It is very good at stopping rust. It can keep magnets safe for over 720 hours in a salt spray test. This test is like making the magnet sit in salty air. We make sure to apply the right magnet coating for lasting protection.

We use this coat for car parts. Cars drive in rain and snow. The coat keeps the magnets strong. One car company said this coat made their magnets 62% less likely to break!

2. Zinc-Nickel Coat

This coat is like a superhero against rust. It has zinc and nickel.

It can last for over 1,200 hours in the salt spray test! This is like many, many years near the sea. This is a crucial aspect of the quality we ensure for our customers at our NdFeB magnets factory.

We use this for wind turbines, the big fans that make power. They sit out in the weather all the time. This coat keeps them working for 10 years!

3. Epoxy Coat

Epoxy is like a tough plastic. it is for industrial machines and household appliances.

It is very good with chemicals. Some chemicals can eat other coats. But epoxy is strong.

We use this for magnets in doctor‘s machines, and for medical devices. The coat keeps the inside super clean!

4. Parylene Coat

This coat is very, very thin. You can barely see it. But it is very strong.

It stops almost all water. It is like a perfect raincoat! we use this coat for aerospace and electronics. We use it for magnets in spaceships. They are in space, for power tools, and for magnetic modules. It can get very cold and very hot in space. This coat can handle that! One company, found parylene keeps magnetic flux stability.

5. Phosphating Coat

This coat is like a helper in the automobile industry.

It does not stop rust all by itself. But it helps other coats stick better.

It is like a sticky tape between the magnet and the coat.

We use this for big machines. The machines shake a lot. This coat stops the main coat from peeling off, and helps the tribological properties. Choosing the correct magnet grade is also essential for these applications.

How We Pick the Right Coat

It is like picking shoes.

- If you are going to the beach, you pick sandals.

- If you are going hiking, you pick boots.

We do the same for magnets.

- If the magnet will be near salt water, we pick a robust protective treatment.

- If the magnet will be inside a clean room, we need a different coat.

We make sure to meet the requirements of industrial magnet warranties and industrial magnet maintenance. We offer inorganic sealants and sacrificial anode coatings. We even can put on tungsten carbide coatings.

We do tests. We spray salty water on the magnets. We see how long the coat lasts. You should always ask for these test reports! This is good for industrial and consumer electronics.

: Simple sentence structure. : Analogy to explain material. : Easy understanding of properties. : Clarification on the function.

Bad Things that Can Happen (And How We Stop Them)

Even with a good coat, things can go wrong. But we know how to fix them!

- Peeling Coat: This is like skin peeling after a sunburn. We make the magnet very clean before we put on the coat. We use a special cleaner called plasma.

- Hydrogen Embrittlement: This makes the magnet weak, like a brittle cookie. We bake the magnet in a special oven. This gets rid of the hydrogen. We use VCI, or vapor corrosion inhibitors.

- Porosity: This is like tiny holes in the coat. Water and air get through. For magnetic shielding requirements we use a layer of nickel under the main coat. This stops the holes. This process is ideal for meeting the needs of electromagnetic interference (EMI) protection in electronics.

We understand magnet brittleness mitigation, and the magnet life cycle. Corrosion under insulation (CUI) is a problem we help to solve, and meet the needs of NdFeB waste management.

Keeping Your Magnets Happy

When you own magnets, you must follow magnet storage guidelines.

- Keep the magnets in a dry place. We have humidity chamber testing.

- Do not let them get too hot or too cold.

- Clean them with a soft cloth. Do not use harsh cleaners.

- We have accelerated corrosion protocols, and we build accelerated aging tests.

We provide industrial magnet warranties, but if you have issues, ask us! We will help.

: Explaining solutions from experience.

Why Pick Us?

We are good at making magnets! These are good in different industries.

- We make NdFeB magnets from start to finish.

- We have special papers (certifications) that show we are good.

- We can make special magnets, just for you!

- We are great at surface roughness control.

- We make customized neodymium magnets, and custom NdFeB magnets.

- We meet the requirements of automotive magnet standards, and aerospace certification. We can make them fast. We offer the full suite of *thermal spray techniques..

How to Buy Our Magnets

- Tell us what you need.

- We will look at your idea.

- We will send you test magnets.

- If you like them, we will make lots for you!

Ask us for a free idea and cost today!

Questions You Might Have

Can you coat magnets that are not squares?

Can you fix old magnets?

The End

Magnets need a good coat to stay strong. We are the best at making these coats. Talk to us about your magnet needs! We offer the very best multi-layer coating systems and magnet demagnetization risks.

We strive to be green, and meet specifications for NdFeB waste management, coating curing temperatures, and magnet surface energy.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.