What Are NdFeB Magnets? An Introduction to Neodymium Iron Boron Magnets

These magnets are a type of rare earth magnet that have revolutionized industries with their exceptional magnetic strength and compact size.In this article, we’ll explore everything you need to know about NdFeB magnets—what they are, how they work, their unique characteristics, and their wide-ranging applications.

Whether you’re an engineer, a student, or simply curious about the science behind magnets, this guide will provide valuable insights into why NdFeB magnets are considered the strongest permanent magnets available today.

Table of Contents

What Are NdFeB Magnets Made Of?

NdFeB magnets are composed of an alloy of neodymium, iron, and boron. This combination creates a material with incredibly high magnetic properties, making it far superior to traditional magnets like ferrite magnets or alnico magnets.

The Science Behind NdFeB Magnets

The strength of NdFeB magnets comes from their atomic structure. The neodymium atoms align in a way that generates a strong magnetic field, while the addition of boron enhances the magnet’s durability and resistance to demagnetization. This unique composition allows NdFeB magnets to achieve a high magnetic strength and energy density.

Fun Fact: NdFeB magnets are part of the rare-earth magnet family, which also includes samarium cobalt magnets. However, NdFeB magnets are more widely used due to their superior strength and cost-effectiveness.

Characteristics of NdFeB Magnets

Exceptional Magnetic Strength

NdFeB magnets are known for their high magnetic strength, which is measured in terms of maximum energy product (MGOe). This makes them ideal for applications requiring compact yet powerful magnets.

Resistance to Demagnetization

Thanks to their high coercivity, NdFeB magnets maintain their magnetism even under challenging conditions, such as exposure to external magnetic fields or high temperatures.

Compact and Lightweight

Compared to other permanent magnets, NdFeB magnets offer the same or greater strength in a smaller size, making them perfect for modern, space-saving designs.

Why Are NdFeB Magnets the Strongest Magnets Available?

The strength of a magnet depends on its material composition and manufacturing process. NdFeB magnets are the strongest permanent magnets available because of their high magnetic properties and energy density. They outperform other types of magnets, such as ceramic magnets and ferrite magnets, in terms of both strength and versatility.

| Magnet Type | Magnetic Strength | Applications |

| NdFeB Magnets | Highest | Electronics, motors, wind turbines |

| Samarium Cobalt | High | Aerospace, high-temperature uses |

| Ferrite Magnets | Moderate | Speakers, household appliances |

| Alnico Magnets | Low | Sensors, instruments |

How Are NdFeB Magnets Manufactured?

The production of NdFeB magnets involves a complex process that ensures their high performance and durability. Here’s a simplified overview:

- Material Preparation: Neodymium, iron, and boron are combined to form an alloy.

- Powdering and Pressing: The alloy is ground into a fine powder and pressed into a mold.

- Sintering: The pressed material is heated to a high temperature to fuse the particles together.

- Magnetization: The material is exposed to a strong magnetic field to align the atoms and create a permanent magnet.

What Are the Different Grades of NdFeB Magnets?

NdFeB magnets are available in various grades, such as N35, N42, and N52, which indicate their magnetic strength and energy product. Higher grades, like N52, offer the strongest magnetic performance.

| Grade | Maximum Energy Product (MGOe) | Applications |

| N35 | 35 | General-purpose uses |

| N42 | 42 | Industrial and technical uses |

| N52 | 52 | High-performance applications |

Internal Link: Learn more about customized NdFeB magnets.

Applications of NdFeB Magnets

Electronics and Consumer Devices

NdFeB magnets are widely used in electronics, including smartphones, headphones, and hard drives. Their compact size and high magnetic strength make them ideal for modern gadgets.Internal Link: Explore their role in consumer electronics.

Renewable Energy

In wind turbines and other renewable energy systems, NdFeB magnets are essential for converting mechanical energy into electricity. Their durability and strength ensure reliable performance in harsh environments.Internal Link: Discover more about NdFeB magnets in wind power.

Automotive Industry

From electric vehicles to advanced driver-assistance systems (ADAS), NdFeB magnets play a crucial role in improving efficiency and performance in the automotive sector.Internal Link: Learn about NdFeB magnets in automotive manufacturing.

How Do Coatings Improve NdFeB Magnets?

Because NdFeB magnets are prone to corrosion, they are often coated with materials like nickel, PTFE, or epoxy. These coatings enhance the magnet’s durability and resistance to environmental factors.

Pro Tip: Always choose a magnet with the appropriate coating for your specific application to ensure long-lasting performance.

What Are the Operating Temperatures of NdFeB Magnets?

The operating temperature of a magnet determines its performance in high-heat environments. Standard NdFeB magnets can operate up to 80°C, but specialized grades like N35UH or N42H can withstand temperatures up to 200°C.

NdFeB Magnets vs. Other Rare Earth Magnets

While NdFeB magnets are the strongest, samarium cobalt magnets offer better performance at high temperatures and greater resistance to corrosion. Here’s a quick comparison:

| Feature | NdFeB Magnets | Samarium Cobalt Magnets |

| Magnetic Strength | Higher | Moderate |

| Corrosion Resistance | Moderate (requires coating) | High |

| Operating Temperatures | Lower (up to 200°C) | Higher (up to 300°C) |

How to Choose the Right NdFeB Magnet for Your Needs

When selecting an NdFeB magnet, consider the following factors:

- Grade: Higher grades like N52 offer stronger magnetic performance.

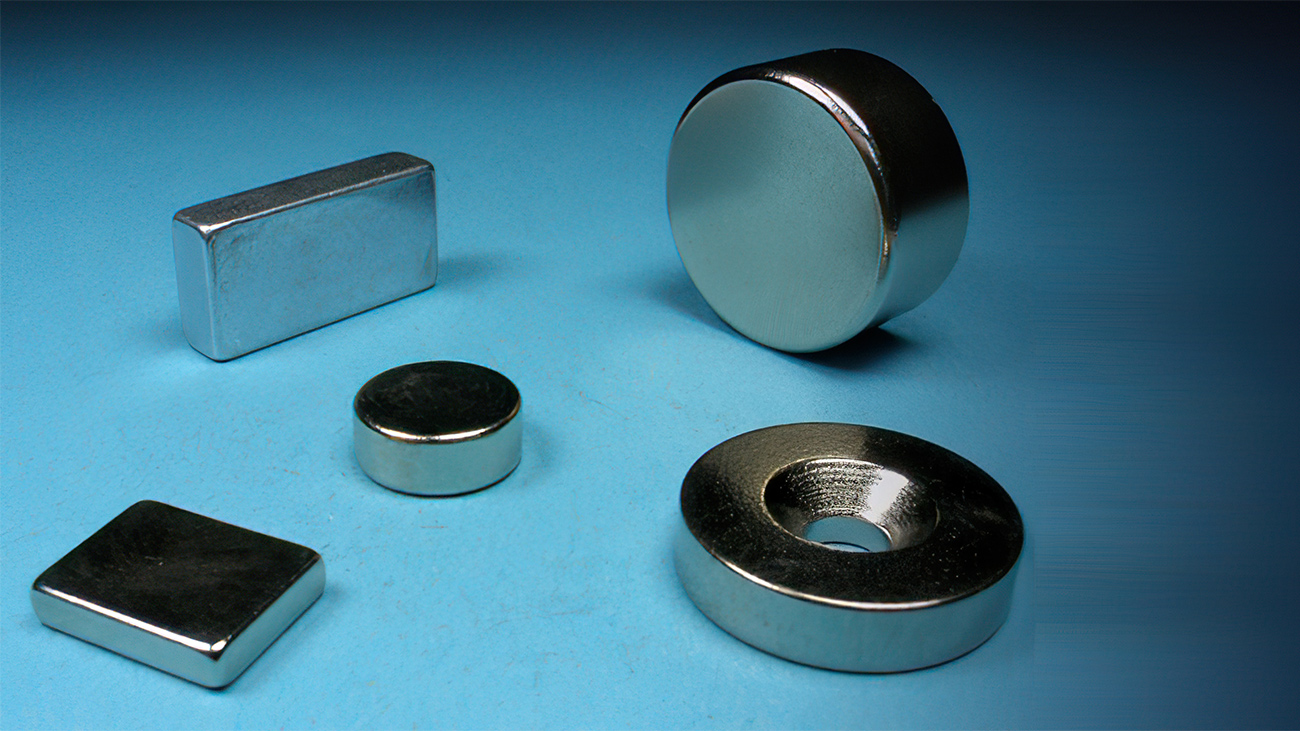

- Size and Shape: Options include disc magnets, ring magnets, and block magnets.

- Coating: Ensure the magnet has a suitable coating for your application.

Internal Link: Learn more about custom neodymium magnets.

Future Trends in NdFeB Magnets

As industries continue to innovate, the demand for NdFeB magnets is expected to grow. Research is focused on improving their corrosion resistance, expanding their operating temperature range, and developing sustainable manufacturing processes.

Key Takeaways

- NdFeB magnets are the strongest permanent magnets available, made from an alloy of neodymium, iron, and boron.

- They are widely used in electronics, renewable energy, automotive, and industrial applications.

- Coatings and grades play a crucial role in enhancing their performance and durability.

- Future advancements aim to make these magnets even more efficient and sustainable.

Explore more about customized magnets for your specific needs:

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.