Unlocking the Power of Custom NdFeB Magnets for Hybrid and Electric Vehicles

These custom magnets, with their high magnetic performance and wide range of applications, are revolutionizing industries, especially in automotive engineering. In this article, we will explore why NdFeB magnets are the preferred choice for electric motors, their advantages, and their role in the growth of hybrid and electric vehicles.This article is a must-read for anyone interested in understanding the science, applications, and future of custom neodymium magnets.

Whether you’re an automotive engineer, a clean energy enthusiast, or a tech enthusiast, you’ll gain valuable insights into how these powerful magnets are shaping the future.

Table of Contents

What Are Neodymium (NdFeB) Magnets?

Neodymium magnets are a type of rare earth magnet made from an alloy of neodymium (Nd), iron (Fe), and boron (B). They are known for their strong magnetic properties, making them the strongest permanent magnets available today. NdFeB magnets are widely used in various industries, including automotive, wind turbines, medical devices, and industrial automation.

Key Features:

- High magnetic strength: These magnets offer unmatched energy density.

- Compact size: They enable the development of smaller and lighter motors.

- Versatility: They are used in everything from electric motors to MRI machines.

Why Are NdFeB Magnets Critical for Electric Motors?

Electric motors, especially those used in hybrid and electric vehicles, rely on the high performance of NdFeB magnets to generate torque and convert electrical energy into mechanical energy. NdFeB magnets provide the strength and efficiency needed to power these motors.

Magnetic Properties:

- High energy density: NdFeB magnets can store significant amounts of magnetic energy, making them ideal for electric motors.

- Resistance to demagnetization: These magnets maintain their performance even under extreme conditions.

Applications in Automotive:

- Powering permanent magnet synchronous motors (PMSMs).

- Reducing the size and weight of motors, which improves vehicle efficiency.

For more details on NdFeB magnets for the automotive industry, visit Custom NdFeB Magnets for Automotive.

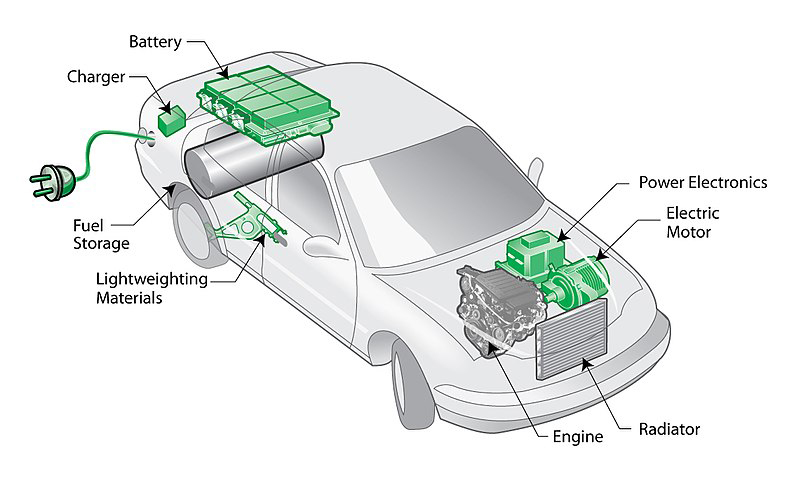

How Do NdFeB Magnets Enhance Hybrid and Electric Vehicles?

The rise of hybrid and electric vehicles has created a demand for lightweight, high-performance magnets. NdFeB magnets are central to meeting this demand due to their ability to deliver consistent torque and power.

Benefits for HEVs:

- Efficiency: NdFeB magnets reduce energy loss, ensuring maximum output.

- Durability: Their resistance to demagnetization allows them to perform reliably over time.

- Compact Design: They enable smaller and lighter motors, contributing to vehicle weight reduction.

For a closer look at NdFeB magnets for hybrid and electric vehicles, check out NdFeB Magnets for Automotive Applications.

Applications of Custom NdFeB Magnets in the Automotive Industry

Custom NdFeB magnets are tailored to meet the specific needs of the automotive industry, from powertrain systems to autonomous driving technologies.

Automotive Applications:

- Electric Motors: Used in electric and hybrid vehicles for propulsion.

- Powertrain Systems: Enhance the efficiency of internal combustion engines in hybrid vehicles.

- ADAS (Advanced Driver Assistance Systems): Enable accurate sensing and actuation.

Why Customization Matters:

Custom magnets ensure optimal performance by matching the magnetic properties to the specific requirements of each application.

The Advantages of Custom NdFeB Magnets

NdFeB magnets offer unparalleled advantages that make them the top choice for high-demand applications.

Key Advantages:

- High Performance: Deliver superior strength and efficiency.

- Temperature Stability: Maintain performance in extreme conditions.

- Wide Range of Applications: Used in medical devices, wind turbines, and industrial motors.

Advantages of Customization: Tailoring the magnet’s size, shape, and magnetic field ensures it meets unique industry requirements.For more on custom solutions, visit Customized NdFeB Magnets.

Types of NdFeB Magnets and Their Features

NdFeB magnets come in various grades and configurations, each with specific features.

Types of NdFeB Magnets:

- Sintered NdFeB: Offers the highest energy product and is widely used in industrial applications.

- Bonded NdFeB: Lightweight and corrosion-resistant, ideal for consumer electronics.

Popular Grades:

- N35-N52: Standard grades for high energy applications.

- N40H-N48H: High-temperature grades for demanding environments.

For a detailed breakdown of grades, visit NdFeB Magnet Properties.

NdFeB Magnets vs. SmCo Magnets: What’s the Difference?

While both NdFeB and SmCo magnets are rare earth magnets, they differ significantly in performance and application.

| Feature | NdFeB Magnets | SmCo Magnets |

| Magnetic Strength | Higher | High but slightly lower |

| Temperature Stability | Moderate | Superior |

| Cost | More affordable | Expensive |

NdFeB magnets are ideal for applications requiring high energy density, while SmCo magnets excel in temperature stability.

How Custom NdFeB Magnets Improve Energy Efficiency

One of the most significant contributions of NdFeB magnets is their ability to enhance energy efficiency, particularly in industrial automation and electric vehicles.

Energy-Saving Features:

- High Power-to-Weight Ratio: Reduces energy consumption.

- Efficiency in Electric Motors: Minimizes energy loss during operation.

For more on energy-efficient solutions, visit NdFeB for Industrial Equipment.

Temperature Stability and Resistance to Demagnetization

Temperature stability is a critical factor for magnets used in demanding environments. NdFeB magnets offer excellent performance, though they require proper selection for high-temperature applications.

High-Temperature Grades:

- N40H-N48H: Ideal for automotive and industrial use.

- N35UH-N40UH: Designed for ultra-high temperature environments.

For more on temperature-stable magnets, visit NdFeB High-Temperature Grades.

The Future of NdFeB Magnets in New Energy Vehicles

The growing demand for clean energy solutions has positioned NdFeB magnets as a cornerstone of innovation in new energy vehicles.

Emerging Trends:

- Integration with Wind Power: NdFeB magnets are being used in wind turbines to generate sustainable energy.

- Advancements in EV Motors: Continuous improvements in magnet technology are driving the next generation of electric motors.

For more on the future of NdFeB magnets, visit NdFeB for Wind Power.

Key Takeaways

- NdFeB magnets are essential for the performance of electric motors in hybrid and electric vehicles.

- Customization ensures optimal performance tailored to specific applications.

- These magnets offer superior magnetic strength, energy efficiency, and temperature stability.

- NdFeB magnets are driving innovation in industries ranging from automotive to renewable energy.

For more information on custom NdFeB solutions, visit Customized NdFeB Magnets.

This article not only showcases the value of NdFeB magnets but also reinforces their importance in shaping the future of technology and sustainability

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.