Unleash the Power of Custom NdFeB Magnets for High-Performance Power Tools

These super strong magnets are prized for their exceptional magnetic strength and versatile applications, making them ideal for industries that demand efficiency, durability, and precision.

In this article, you’ll discover how custom NdFeB magnets are tailored to meet the needs of power tools, why they outperform other magnet types, and how you can find the perfect magnetic solution for your specific needs.Read on to learn about the science, benefits, and customization options for NdFeB magnets, and explore how they create efficient and effective solutions for modern machinery.

Table of Contents

What Are NdFeB Magnets and Why Are They Special?

NdFeB magnets, also known as neodymium magnets, are a type of rare earth permanent magnet made from an alloy of neodymium, iron, and boron. These magnets are renowned for their high magnetic strength, which is unmatched in the industry.

Key Features:

- Super Strong Magnetic Properties: NdFeB magnets are the strongest permanent magnets available, making them indispensable for high-performance applications.

- Versatility: They come in various shapes and sizes, such as ring magnets, bonded NdFeB, and sintered NdFeB magnets, catering to a wide range of industries.

NdFeB magnets are widely used in applications requiring compact yet powerful magnetic solutions, and their customizability ensures that specific needs are met.

How Do Neodymium Magnets Work in Power Tools?

Power tools rely on strong magnets to convert electromagnetic energy into mechanical power. Neodymium magnets, with their high magnetic strength and corrosion resistance, are ideal for motors and other critical components in power tools.

Why They Work:

- Magnetic Force: The high magnetic force of NdFeB magnets enables power tools to operate efficiently, even under heavy loads.

- Compact Size: Their ability to generate strong fields in small sizes makes them perfect for lightweight and portable tools.

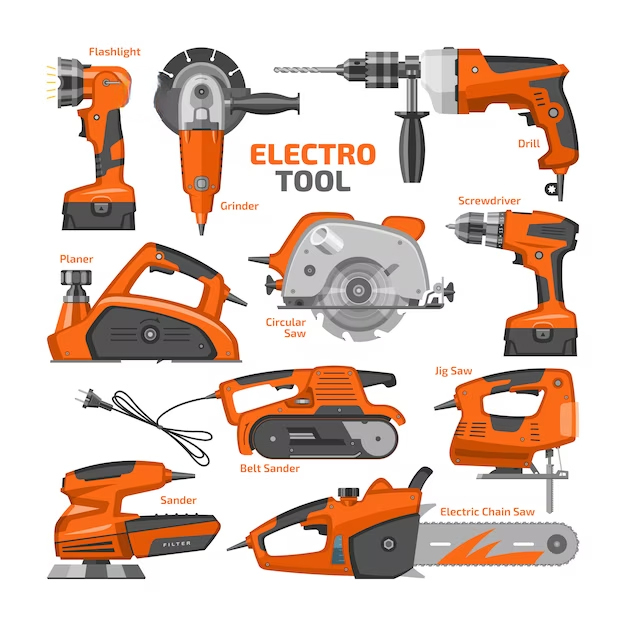

Whether it’s a cordless drill or an industrial-grade saw, custom NdFeB magnets provide the power and precision needed for demanding tasks.

Why Choose Custom NdFeB Magnets for Power Tools?

Customization is crucial for meeting the specific requirements of power tools. Each tool has unique demands, and custom magnets ensure optimal performance.

Benefits of Customization:

- Tailored Magnetic Properties: Adjustments to magnetization and pull force can enhance tool performance.

- Shape and Size: From ring magnets to disc and block magnets, customization allows for perfect integration into tool designs.

- Corrosion Resistance: Custom coatings, such as nickel or epoxy, protect magnets from wear and tear.

By working with a reliable supplier, you can get magnets designed specifically for your tools’ needs.

The Role of Magnetic Strength in High-Performance Power Tools

The magnetic strength of NdFeB magnets is a critical factor in determining their effectiveness in power tools. N52-grade magnets, for example, offer unparalleled strength, making them suitable for heavy-duty applications.

Why Magnetic Strength Matters:

- Efficiency: High-strength magnets enable tools to perform tasks with minimal energy loss.

- Durability: Strong magnets maintain their performance over time, even under stress.

For applications that demand both power and precision, the superior magnetic properties of NdFeB magnets are unmatched.

Corrosion Resistance and Durability in NdFeB Magnets

One of the few challenges with NdFeB magnets is their susceptibility to corrosion. However, advancements in coating technology have significantly improved their durability.

Corrosion-Resistant Coatings:

- Nickel-Copper-Nickel (NiCuNi): A popular coating that provides excellent resistance against moisture and oxidation.

- Epoxy: Ideal for applications requiring additional protection in harsh environments.

These coatings ensure that your custom neodymium magnets remain effective and long-lasting, even in demanding conditions.

NdFeB Magnet Manufacturing: How Are They Made?

The manufacturing process of NdFeB magnets is a fascinating combination of science and precision. Most sintered NdFeB magnets are created through a process involving alloying, pressing, sintering, and machining.

Key Steps:

- Alloying: The raw materials, including neodymium, iron, and boron, are melted into an alloy.

- Pressing and Sintering: The alloy is pressed into shape and sintered to enhance its strength.

- Machining and Coating: Magnets are cut to the desired specifications and coated for durability.

This meticulous process ensures that each magnet meets the highest standards of magnetic performance.

Common Applications of Custom Neodymium Magnets

NdFeB magnets are not limited to power tools. Their versatile applications extend to various industries, including:

- Electric Vehicles: Motors and charging systems.

- Medical Devices: MRI machines and surgical tools.

- Wind Turbine Generators: High-efficiency energy generation.

Their ability to deliver consistent, high-performance results makes them a favorite in multiple sectors.

What is N52 Grade and Why Does It Matter?

N52-grade magnets represent the pinnacle of NdFeB magnet performance. They offer the highest magnetic strength available, making them ideal for demanding applications.

Advantages:

- Superior Strength: Ideal for compact tools requiring maximum power.

- Wide Temperature Range: Suitable for environments with fluctuating temperatures.

When precision and strength matter most, N52-grade magnets are the top choice.

How to Customize NdFeB Magnets for Specific Applications

Customization adds value by tailoring magnets to exact specifications. Whether you need specific shapes and sizes or enhanced corrosion resistance, customization ensures that your magnets perform exactly as needed.

Customization Options:

- Magnetization: Adjust the direction and strength of the magnetic field.

- Coatings: Choose from nickel, epoxy, or other materials for added durability.

- Shapes: From ring magnets to blocks, customization ensures perfect integration.

Where to Find Reliable NdFeB Magnet Suppliers?

Finding the right supplier is key to obtaining high-quality custom NdFeB magnets. Look for manufacturers with expertise in magnet manufacturing and a proven track record.

Recommendations:

These suppliers offer advanced equipment and a wide range of customization options to meet any requirement.

Key Takeaways

- NdFeB magnets are the strongest rare earth magnets, ideal for high-performance applications.

- Customization ensures that magnets meet the specific needs of power tools.

- N52-grade magnets provide superior strength and efficiency.

- Reliable coatings enhance corrosion resistance and durability.

- Work with trusted suppliers to get high-quality, customized solutions.

By understanding the unique benefits and features of NdFeB magnets, you can harness their power to create efficient, reliable, and high-performance tools. For more information, explore the customization options available at trusted suppliers like Customized NdFeB Magnets.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.