Understanding Magnets: The Basics, Grades, and Their Applications

This article delves deep into the world of magnets, covering their basics, grades, types, and how they function. Whether you’re a curious learner or someone looking to shop neodymium magnets for your application, this guide has you covered.

Table of Contents

What You’ll Learn in This Article:

- What are magnets, and how do they work?

- The difference between permanent magnets and other types.

- Why neodymium magnets are the strongest magnets available.

- How magnetic field strength and magnet grade impact performance.

- Practical applications of magnets in industries like automotive, aerospace, and renewable energy.

What Is a Magnet, and How Does It Work?

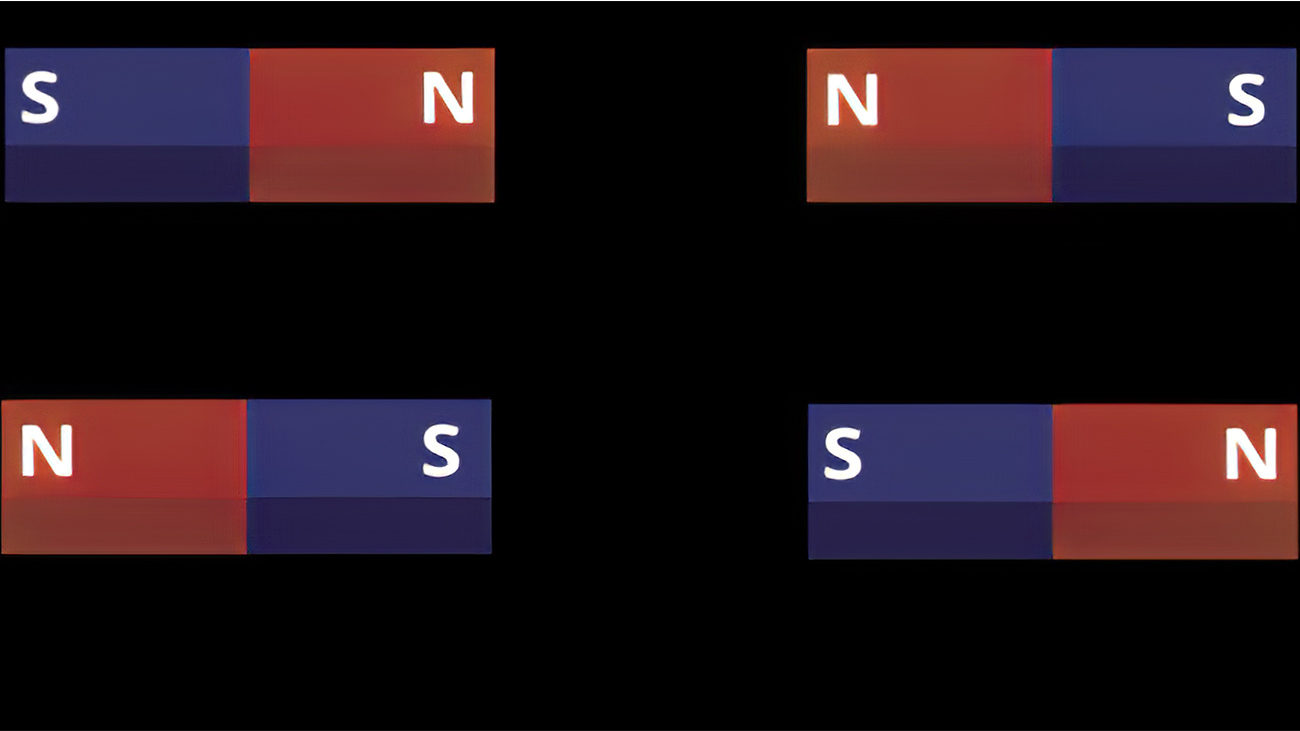

A magnet is an object that produces a magnetic field, which attracts certain materials like iron, nickel, and cobalt. The science behind magnets lies in the alignment of their microscopic magnetic domains. These domains combine to create a strong magnetic field. The poles of a magnet—north and south—determine their behavior: like poles repel, and unlike poles attract.

How Magnets Create a Magnetic Field

Magnets produce a magnetic field due to the movement of electric charges within their material. The direction of the field is represented by field lines, which flow from the north pole to the south pole. This field is responsible for the force between two magnets and the ability to attract or repel objects.

The Basics of Magnet Grades and Types

Understanding magnet grade is key when choosing the right magnet for your application. Magnet grades, such as N35, N42, and N52, indicate the strength of a magnet. Higher grades mean stronger magnetic properties and greater pull force.

Common Types of Magnets

- Neodymium Magnets: Known as the strongest rare earth magnets, these are widely used in industrial equipment, wind turbines, and medical devices.

- Samarium Cobalt Magnets: A type of permanent magnet with excellent thermal stability, ideal for aerospace and automotive applications.

- AlNiCo Magnets: Combination of aluminum, nickel, and cobalt, often used in sensors and loudspeakers.

- Ceramic Magnets: Cost-effective and durable, commonly used in household appliances.

Neodymium magnets and samarium cobalt magnets are particularly popular because of their strong magnetic field and resistance to demagnetization.

Why Are Neodymium Magnets So Powerful?

Neodymium magnets are a type of rare earth magnet made from neodymium, iron, and boron. They are incredibly strong because their crystalline structure allows a high degree of magnetic domain alignment.

Applications of Neodymium Magnets

- Wind Turbines: Used as motor magnets for efficient energy conversion.

- Electronics: Found in phones, laptops, and headphones.

- Medical Devices: Essential for MRI machines and surgical instruments.

For more information, explore Custom Neodymium Magnets.

Permanent Magnets vs. Electromagnets

Permanent magnets are made from materials like neodymium and samarium cobalt, which retain their magnetic properties indefinitely. On the other hand, electromagnets require an electric current to produce a magnetic field.

Why Choose Permanent Magnets?

- Durability: Permanent magnets are long-lasting and reliable.

- Energy Efficiency: They don’t require electricity to maintain their magnetic field.

To learn more, check out Customized NdFeB Magnets.

How Are Magnets Made?

The process of making magnets varies depending on the type. For example:

- Neodymium Magnets: Manufactured using a method called sintering, where powdered materials are compressed and heated.

- Injection Molded Magnets: Created by molding magnetic material into desired shapes.

- Flexible Magnets: Made from rubber and ferrite powder, offering flexibility and versatility.

What Are Magnetic Assemblies?

Magnetic assemblies combine multiple magnets into a single unit, enhancing their functionality. These are often used in industrial motors, wind turbines, and other high-performance applications.Learn more about Magnetic Systems.

Applications of Magnets in Everyday Life

Automotive Industry

Magnets are critical in electric vehicles, where they are used in motors and sensors. NdFeB magnets are ideal for powertrain systems and autonomous driving technologies.

Renewable Energy

Magnets are at the heart of wind turbines and tidal energy generators. They help convert mechanical energy into electricity efficiently.

Aerospace

In aerospace engines and propulsion systems, samarium cobalt magnets are preferred for their heat resistance and strength.

How to Choose the Right Magnet for Your Application

When shopping for magnets, consider the following:

- Magnet Grade: Higher grades like N50 and N52 offer stronger pull force.

- Magnet Material: Neodymium is ideal for high-performance needs, while ceramic is more cost-effective.

- Coating: Protective coatings like PTFE or Teflon enhance durability.

Explore options at Magnet Grade.

FAQs About Magnets

1. What is the strongest type of magnet?

Neodymium magnets are the strongest magnets commercially available.

2. Can magnets lose their strength over time?

Yes, exposure to high temperatures or physical damage can demagnetize the magnet.

3. What are flexible magnets used for?

Flexible magnets are commonly used in advertising, signs, and magnetic sheets.

Conclusion and Key Takeaways

Magnets play a vital role across industries, from powering wind turbines to enabling modern electronics. Understanding the basics of magnets, their grades, and their applications can help you make informed decisions when choosing the right magnet for your needs.

Summary:

- Magnets produce a magnetic field that attracts certain materials.

- Neodymium magnets are the strongest and most versatile.

- Magnet grades indicate strength and performance.

- Applications span industries like automotive, renewable energy, aerospace, and more.

- Always choose magnets based on grade, material, and application requirements.

For customized solutions, visit Customized NdFeB Magnets.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.