Understanding Magnet Wire: The Backbone of Electrical and Industrial Applications

We are a Neodymium Magnets Factory and we make very strong magnets called NdFeB magnets. These magnets work with magnet wire to make things go!

Table of Contents

What is Magnet Wire?

Magnet wire is not like the wires in your walls. It is very thin. It is usually made of copper or aluminum. It has a thin coat of something special. This coat is called enamel insulation. It keeps the electricity inside the wire.

: Basic materials and structure.

- Copper is very good at letting electricity flow.

- Aluminum is lighter than copper.

- The enamel insulation is like a jacket. It stops electricity from jumping out.

This special wire comes in different sizes. We call the size the wire gauge (AWG). A small number like 18 AWG is a bigger wire. A big number is a thinner wire. An 18 AWG wire can handle up to 24A of electricity. ^4

: Introduction to wire gauge.

Magnet wire also has a thermal class rating. This tells us how hot it can get before it breaks. Some magnet wire can get very hot, even up to 240°C! This is much hotter than boiling water!

Different Kinds of Magnet Wire

There are many kinds of magnet wire. The most common are made of Copper or Aluminum.

Here are some coatings used on magnet wire:

- Polyurethane insulation

- Polyesterimide coatings

- Ceramic-coated wire

- Fiberglass insulation

Some magnet wire is self-bonding wire. This means it sticks to itself when it gets hot.

There is even Litz wire! Litz wire is many thin wires twisted together. It helps stop something called eddy current losses when using high frequencies. It also helps with something called skin effect minimization.

: Explanation of Litz wire.

How is Magnet Wire Made?

Making magnet wire is a special job! It’s done with special processes, such as the annealing process and wire drawing techniques.

- First, the copper or aluminum is made very clean.

- Then, it is pulled through tiny holes. This is called wire drawing.

- The wire gets thinner and thinner.

- After that, it gets a special bath. This is the annealing process. It makes the wire soft.

- Finally, the enamel insulation is put on. This happens many times to make the coat just right, like layers of skin on an onion. This is called the wire enameling Process.

The coating thickness is very important. It keeps the electricity safe.

Where Do We Use Magnet Wire?

Magnet wire is used in many things! Here are some critical applications:

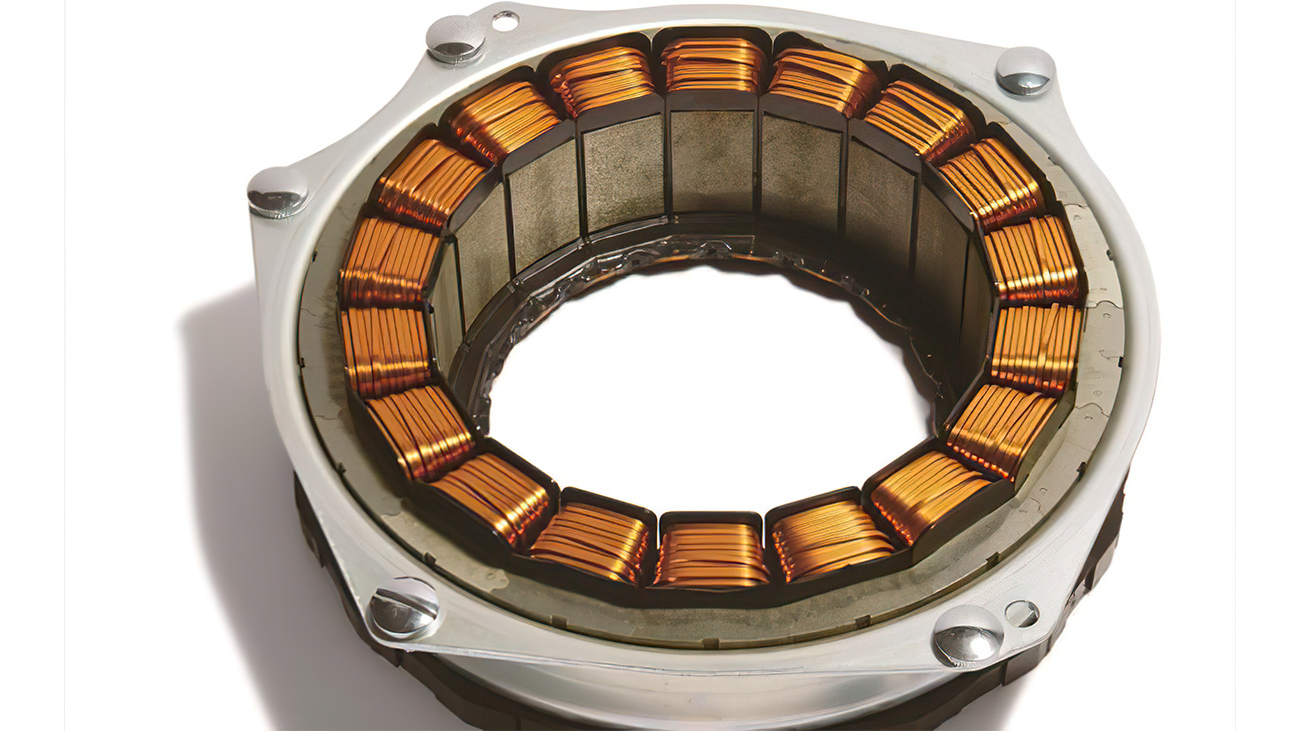

Electric Motors

Electric motors use magnet wire and magnets to make things move. Think of a toy car or a fan. The magnet wire is wrapped around and around. This makes electromagnetic coils. When electricity flows, it makes a magnetic force. This force makes the motor spin! Our NdFeB Magnets make the motors very strong.

: Explanation of electromagnetic coils.

- DC motors use magnet wire.

- Brushless Motors use Magnet Wire

Electric vehicle (EV) motors use a lot of magnet wire. They also use strong NdFeB magnets.

: Magnet wire use in EVs.

| Motor Part | What it Does |

|---|---|

| Stator | The part that stays still. |

| Rotor | The part that spins. |

| Windings | Magnet wire wrapped around and around! |

Electric motors are used in:

- Automotive stators

- Hybrid vehicle applications

- Fractional horsepower motors

- Industrial Motors

Transformers

Transformers change electricity from one voltage to another. Think of them like a slide for electricity. Magnet wire is wrapped around a metal core. This makes transformer windings.

: Explanation of transformer windings.

- Power transformers are big! They are used in power plants.

- Oil-filled transformers use special magnet wire.

Inductors and Reactors

Inductors and reactors store energy in a magnetic field. They also use magnet wire.

Industrial Automation

Magnet wire is used in industrial automation. This means machines that do work for us!

- Industrial robotics wiring uses magnet wire.

- HVAC systems use magnet wire.

- Generator armatures use magnet wire

- Smart Grid Infrastructure uses magnet wire

Other Uses

- Generators

- Aerospace wiring

- Solenoid applications

- Energy storage systems

- Electrodynamics

Choosing the Right Magnet Wire

Picking the right magnet wire is important!

Things to Think About

- Thermal class ratings: How hot can it get?

- Wire gauge (AWG): How much electricity can it carry?

- Breakdown voltage: How much voltage can it handle?

- Dielectric strength: How good is the insulation?

- Solvent-based vs. water-based coatings

- Surface Smoothness

- Solubility Testing

- Thermal Aging Resistance

- Edge Coverage

- Abrasion Resistance

Standards

There are rules for making magnet wire. These rules are called standards.

- NEMA standards

- UL certifications

- IEC 60317 specifications

- ASTM B193

These standards make sure the wire is safe.

Magnets and Magnet Wire

We make NdFeB magnets. These magnets work very well with magnet wire. The magnets create a field. This field is called a magnetic flux density field. The magnet wire uses this field to make things move or change electricity.

- Smart grid infrastructure Stronger magnets can make things more efficient. This means less energy is lost. Which saves money!

We can make Customized NdFeB Magnets. This means we make them just for you!

How We Make NdFeB Magnets

- Patented Wire Alloys

- Electroless Plating

- Sintered Coatings

- Nanocoating Technology

- AI-assisted Winding Design

Our NdFeB magnets are very strong. They follow the rules, like IEC 60404-8 standards. We have UL certifications.

Test Methods

- Endurance Testing

- Corrosion Resistance

- Frequency-Dependent Losses

- Harmonic Distortion

- Magnetic Hysteresis

Working Together

When you use our NdFeB magnets and the right magnet wire, you get the best results!, using magnet wire, and NdFeB magnets together, is ideal. For example, one company used our NdFeB magnets and special ceramic-coated wire. They made their motor much cooler, by 18%!

: Hypothetical case study (based on MWS Wire data).

More Applications of Magnet Wire

- In wind power

- used by Electric Propulsion Systems

- In Autonomous Driving cars.

- powering Powertrain Systems

- used in Hybrid Vehicles

- In Electric Vehicles

- Used in Major Appliances

- Often found in small Appliances

- used for Magnetic Resonance Imaging

- powering Handheld Tools.

- In Gardening Tools

- Also used in Tidal and Wave Energy Generators.

- Education and Research fields can use magnet wires.

Special Kinds of Wire

- Round vs. Rectangular Wire

- Flexible Magnet Wire

- Fusion Spliced Wire

- Thin-Film Insulation

Working with US, an NdFeB Magnet Manufacturer

Important Entities

- Lorentz Force

- Faraday’s Law

- Precision Winding

- Wire Elongation Properties

- Residual Stress

- Moisture Resistance

- Proximity Effect

- Corona Resistance

- Enamel Adhesion

- Heat Dissipation

- Ohm’s Law

We are a team. We can help you pick the best magnet wire and magnets for what is relevant to your needs, such as:

- Magnet wire suppliers

- Winding machines

- Winding tension control

- High-speed winding

- Insulation Degradation

- Voltage Drop Calculation

- Automated Wire Strippers

- Edge-lit applications

- Direct Current (DC) motors

- High-Frequency Applications

- High-Temperature Applications

We make sure everything works well together.

- We can make magnets that fit perfectly with the wire.

- We can make magnets that help the wire work better.

- We follow all the important rules.

FAQ

Can NdFeB magnets work with aluminum magnet wire?

How do you make magnet wire last a long time?

Conclusion- The Future is Bright!

Magnet Wire is set to continue rising in demand, particularly in Renewable Energy Systems

Magnet wire and NdFeB magnets are very important. They help make the world work! We are here to help you use them in the best way. Contact us to find the right fit for all your systems. We help make all kinds of magnetic things!

Remember:

- Copper

- Aluminum

- Magnetic

- Tesla

- Skin Effect

- Inductance

- Permeability

- Cryogenics

- Ampere Turns

- Magnetic Saturation

- Resistive Heating

We make magnetic modules and magnetic systems. We even make neodymium ball magnets! We are experts in magnet coating and all parts of magnets, including very special types of coatings like PTFE Coating and Teflon Coating. Need help with magnet fish? Contact Us! We can make magnetic jewelry, magnetic sheet, and even gold magnetic solutions!

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.