Selecting Different Shapes of Neodymium Magnets: A Comprehensive Guide

This guide will help you understand the different shapes of neodymium magnets, their unique properties, and how to choose the right magnet for your needs.

Whether you’re working on an industrial project, a household application, or a specialized device, this article will provide the insights you need to make an informed decision.

Table of Contents

Why Does the Shape of a Neodymium Magnet Matter?

The shape of a magnet directly influences its magnetic field, strength, and how it interacts with other materials. Different shapes are tailored for specific applications, ensuring optimal performance. For example, a ring magnet is ideal for motors, while a disc magnet is commonly used in sensors and speakers.

Key Factors Affected by Magnet Shape:

- Magnetic Field Distribution: The shape determines how the magnetic field is concentrated and distributed.

- Application Suitability: Certain shapes are better suited for specific tasks, such as holding, lifting, or rotating.

- Ease of Integration: The shape affects how easily the magnet can be incorporated into a design or device.

Understanding the different shapes of neodymium magnets is crucial for selecting the right one for your project.

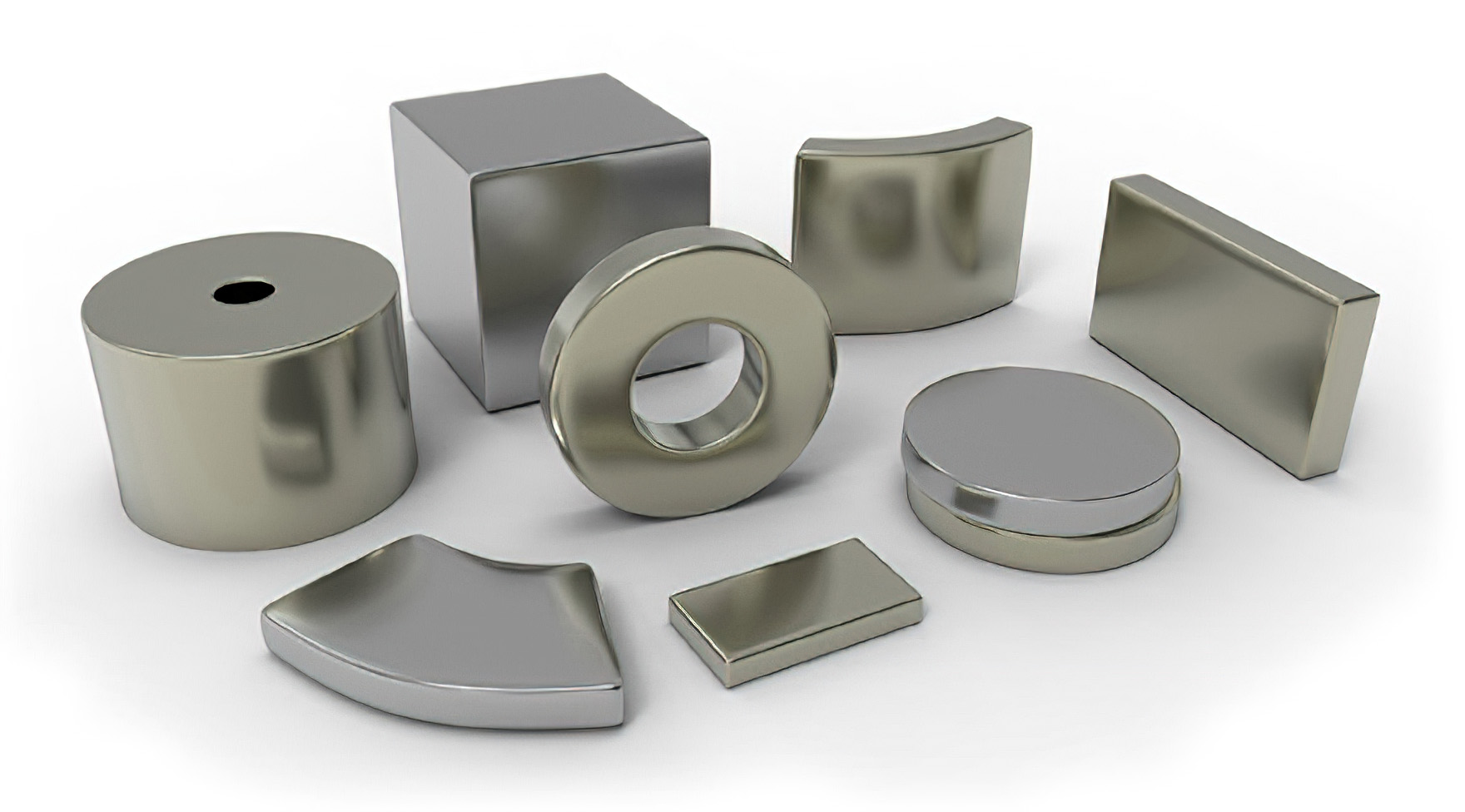

What Are the Common Shapes of Neodymium Magnets?

Neodymium magnets come in a variety of shapes, each designed for specific applications. Here are the most commonly used shapes:

| Shape | Description | Applications |

| Disc Magnets | Circular and flat, with a strong magnetic field on the flat surfaces. | Sensors, speakers, and holding applications. |

| Ring Magnets | Similar to disc magnets but with a hole in the center. | Motors, generators, and scientific experiments. |

| Block Magnets | Rectangular or square, offering a uniform magnetic strength. | Industrial equipment, magnetic separators. |

| Cylindrical Magnets | Long and rod-shaped, with a concentrated magnetic field at the ends. | Medical devices, sensors, and actuators. |

| Sphere Magnets | Perfectly round, with a uniform magnetic field in all directions. | Toys, educational tools, and research. |

| Horseshoe Magnets | U-shaped, designed to maximize magnetic strength at the poles. | Lifting and holding heavy objects. |

Each shape has unique properties that make it suitable for specific tasks. Let’s explore these shapes in more detail.

What Are Disc Magnets and Their Uses?

Disc magnets are among the most commonly used neodymium magnets. These magnets are circular and flat, with their magnetic field concentrated on the flat surfaces.

Features of Disc Magnets:

- Strong Magnetic Field: Ideal for applications requiring a concentrated pull force.

- Compact Design: Easy to integrate into small devices.

Applications of Disc Magnets:

- Speakers and Audio Equipment: Disc magnets are circular in shape, making them perfect for producing sound in speakers.

- Sensors: Their compact size and strong pull make them ideal for precision sensing.

- Holding Applications: Used in refrigerator magnets and other holding devices.

For more information on customized neodymium disc magnets, visit our Customized NdFeB Magnets.

What Are Ring Magnets and Why Are They Popular?

Ring magnets are similar to disc magnets but feature a hole in the center, which allows them to be mounted on shafts or rods. These magnets are widely used in applications requiring rotational motion.

Features of Ring Magnets:

- Hole in the Center: Enables easy mounting and integration.

- High Magnetic Strength: Provides a strong pull force despite the hole.

Applications of Ring Magnets:

- Motors and Generators: Neodymium ring magnets are essential in electric motors and generators.

- Scientific Experiments: Used in setups requiring precise magnetic fields.

- Medical Devices: Commonly found in MRI machines and other diagnostic tools.

For high-quality neodymium ring magnets, check out our Custom NdFeB Magnets.

What Are Block Magnets and Their Applications?

Block magnets, also known as rectangular or square magnets, are versatile and offer a uniform magnetic strength across their surface.

Features of Block Magnets:

- Uniform Magnetic Field: Ideal for applications requiring consistent pull force.

- Durable Design: Resistant to wear and tear.

Applications of Block Magnets:

- Industrial Equipment: Used in magnetic separators and lifting devices.

- Construction: Ideal for holding and positioning materials.

- Magnetic Assemblies: Commonly used in custom magnetic setups.

How to Choose the Right Magnet for Your Application?

Selecting the right neodymium magnet involves considering several factors, including the shape, size, and magnetic strength.

Factors to Consider:

- Application Requirements: Determine the specific task the magnet will perform.

- Magnetic Strength: Choose a magnet with the appropriate pull force.

- Size and Shape: Ensure the magnet fits the design and provides the desired performance.

For customized solutions, explore our Customized Neodymium Magnets.

What Are Cylindrical Magnets and Their Benefits?

Cylindrical magnets, also known as rod magnets, are long and narrow, with a concentrated magnetic field at the ends.

Features of Cylindrical Magnets:

- Focused Magnetic Field: Ideal for applications requiring pinpoint accuracy.

- Compact Design: Easy to integrate into small devices.

Applications of Cylindrical Magnets:

- Medical Devices: Used in diagnostic tools and implants.

- Sensors and Actuators: Provide precise motion control.

- Educational Tools: Commonly used in experiments and demonstrations.

What Are Sphere Magnets and Their Unique Properties?

Sphere magnets are perfectly round, offering a uniform magnetic field in all directions. These magnets are often used in creative and educational applications.

Features of Sphere Magnets:

- Uniform Magnetic Field: Provides consistent pull force in all directions.

- Aesthetic Appeal: Often used in toys and decorative items.

Applications of Sphere Magnets:

- Toys and Games: Popular in magnetic building sets.

- Educational Tools: Used to demonstrate magnetic principles.

- Research: Ideal for experiments requiring uniform fields.

How Do Rare Earth Magnets Compare to Ferrite Magnets?

Rare earth magnets, such as neodymium magnets, are significantly stronger than ferrite magnets. While ferrite magnets are more affordable, they lack the magnetic strength and durability of neodymium magnets.

Comparison Table:

| Property | Neodymium Magnets | Ferrite Magnets |

| Magnetic Strength | Very High | Moderate |

| Durability | Resistant to demagnetization | Prone to demagnetization |

| Cost | Higher | Lower |

| Applications | High-performance devices | General-purpose applications |

For high-performance applications, neodymium magnets are the preferred choice.

What Are the Coatings for Neodymium Magnets?

To enhance durability and prevent corrosion, neodymium magnets are often coated with materials like nickel, zinc, or epoxy.

Common Coatings:

- Nickel: Provides a shiny finish and excellent corrosion resistance.

- Epoxy: Offers additional protection in harsh environments.

- Zinc: A cost-effective option for basic protection.

For more details on coatings, visit our Magnet Coating Guide.

Key Takeaways

- Neodymium magnets come in various shapes, including disc, ring, block, cylindrical, and sphere magnets.

- The shape of a magnet affects its magnetic field, strength, and application suitability.

- Disc magnets are ideal for sensors and speakers, while ring magnets excel in motors and generators.

- Block magnets are versatile and commonly used in industrial applications.

- Rare earth magnets outperform ferrite magnets in strength and durability.

For customized solutions, explore our Customized NdFeB Magnets.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.