Rare Earth Permanent Magnets: The Strongest Magnets for Modern Applications

From powering electric vehicles to enabling efficient wind turbines, these magnets are the backbone of many advanced technologies. But what makes them so unique, and why should you care? This comprehensive guide explores the fascinating world of rare earth permanent magnets, their materials, applications, and future potential.

Table of Contents

What Are Rare Earth Permanent Magnets?

Rare earth permanent magnets are a type of magnet made from rare earth elements like neodymium and samarium. These magnets are known for their strong magnetic properties and are among the strongest permanent magnets available today. Unlike conventional magnets like ferrite or alnico magnets, rare earth magnets offer superior magnetic strength, stability, and resistance to demagnetization.

Types of Rare Earth Magnets: Neodymium and Samarium Cobalt

Rare earth magnets are primarily divided into two types:

- Neodymium Magnets (NdFeB)

Neodymium magnets are the most widely used rare-earth magnets due to their excellent size-to-strength ratio and affordability. They are made from an alloy of neodymium, iron, and boron (NdFeB). These magnets are perfect for applications that require strong magnetic properties in compact sizes, such as electric motors, electronics, and medical devices. - Samarium Cobalt Magnets (SmCo)

Samarium cobalt magnets are another type of rare earth magnet. While they offer slightly lower magnetic strength than neodymium magnets, they are highly stable at high temperatures and provide excellent corrosion resistance. SmCo magnets are ideal for applications in aerospace, automotive, and industrial environments where temperature stability is critical.

How Are Rare Earth Magnets Made?

The production of rare earth magnets involves advanced processes:

- Mining Rare Earth Elements

Rare earth elements like neodymium and samarium are mined from ores such as bastnäsite and monazite. These elements are part of the world’s supply of rare earth metals, which are critical for magnet manufacturing. - Alloying

Neodymium or samarium is combined with other elements like iron, boron, or cobalt to create alloys with unique magnetic strength and physical properties. - Magnetization

The alloy is processed and magnetized to achieve its final magnetic properties. This involves exposing the material to a strong magnetic field to align the domains. - Protection and Coating

To protect the magnets from corrosion and damage to the magnets, coatings like nickel, PTFE, or epoxy are applied. This step ensures durability and extends the lifespan of the magnets.

Why Are Rare Earth Magnets So Powerful?

Rare earth magnets derive their magnetic strength from the unique properties of their materials. Rare earth elements have unpaired electrons in their atomic structure, which contributes to their strong magnetic fields. Additionally, these magnets are designed with precise magnetization techniques to maximize their performance.

Applications of Rare Earth Permanent Magnets

Rare earth magnets are used across various industries due to their versatility and strength. Here are some of their most significant applications:

1. Automotive Industry

Rare earth magnets play a crucial role in the automotive sector, especially in electric vehicles (EVs) and hybrid vehicles. Neodymium permanent magnets are used in powertrain systems, motors, and sensors to improve energy efficiency.Internal Link: Learn more about custom NdFeB magnets for automotive.

2. Wind Power Generation

In wind turbines, neodymium magnets are used in permanent magnet synchronous generators to convert wind energy into electricity efficiently. Their lightweight and high magnetic strength make them ideal for large-scale wind power systems.Internal Link: Discover how NdFeB magnets are used in wind power.

3. Consumer Electronics

Rare earth magnets are integral to modern electronics. They are found in speakers, headphones, hard drives, and mobile devices. Disc magnets and cylinder magnets are commonly used in these applications for their compact size and strong pull force.Internal Link: Check out customized NdFeB magnets for electronics.

4. Aerospace Industry

The aerospace sector relies on samarium cobalt magnets for their stability at high temperatures and resistance to demagnetization. They are used in electric propulsion systems, sensors, and control systems.Internal Link: Read more about NdFeB applications in aerospace.

5. Medical Devices

Rare earth magnets are vital in medical applications like MRI machines and surgical robots. Their strong magnetic properties enable precise and reliable performance in critical environments.

How to Choose the Right Magnet for Your Application

Selecting the right magnet depends on several factors, including:

- Magnet Strength: Neodymium magnets are the strongest magnets available, making them suitable for high-performance applications.

- Operating Temperature: For high-temperature environments, samarium cobalt magnets are the better choice.

- Corrosion Resistance: Magnets with a protective coating like nickel or PTFE offer better durability.

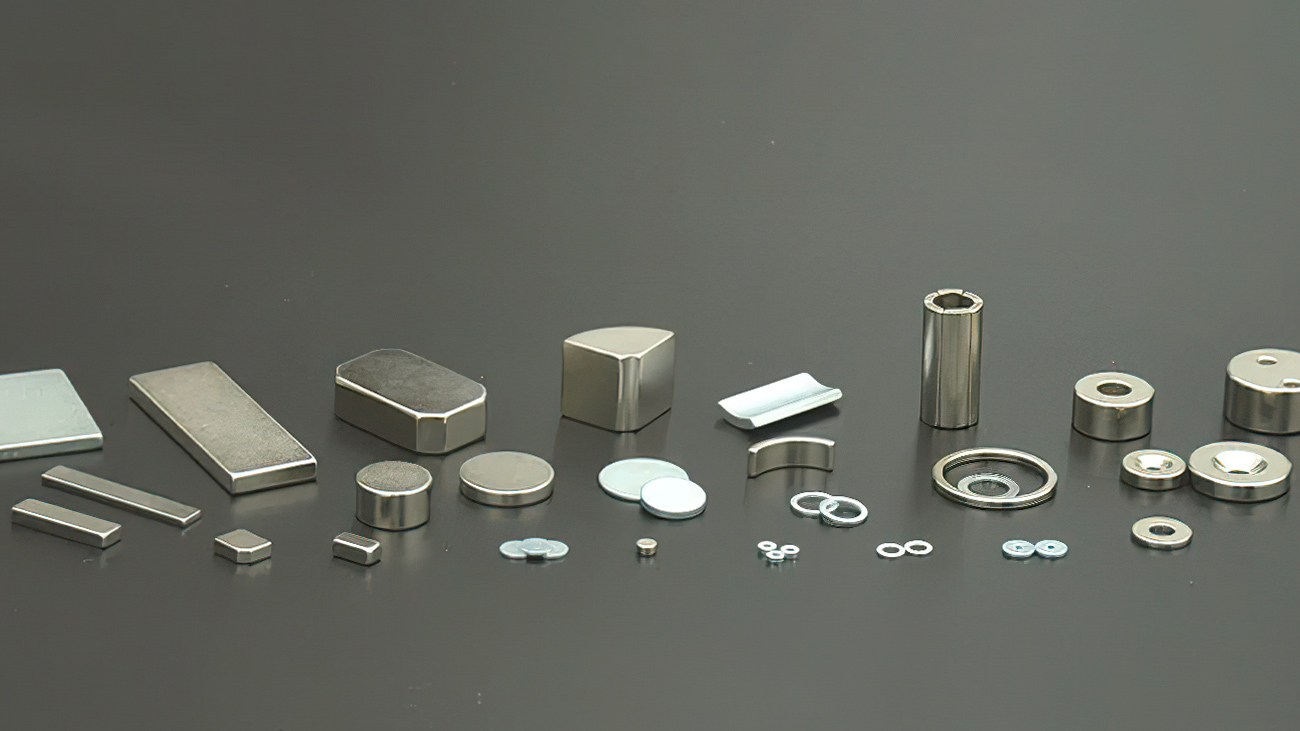

- Size and Shape: Magnets range in size and shape, including disc magnets, cylinder magnets, and ring magnets, to fit specific applications.

Comparing Neodymium and Samarium Cobalt Magnets

| Feature | Neodymium Magnets | Samarium Cobalt Magnets |

| Magnetic Strength | Highest | Moderate |

| Corrosion Resistance | Requires coating | High |

| Temperature Stability | Up to 80°C | Up to 350°C |

| Cost | Affordable | Expensive |

Magnet Safety: Handling and Storage

Rare earth magnets are incredibly strong and can cause injury if not handled carefully. Follow these safety tips:

- Keep Away from Electronics: Strong magnetic fields can damage electronic devices.

- Use Protective Gear: Gloves and safety glasses are recommended when handling large magnets.

- Proper Storage: Store magnets in a secure location, away from metal objects and other magnets.

Challenges and Sustainability of Rare Earth Magnets

While rare earth magnets are essential for many industries, their production poses environmental and geopolitical challenges:

- Mining Impact: Extracting rare earth elements can cause significant environmental damage.

- Geopolitical Issues: The majority of the world’s supply of rare earth metals comes from limited regions, leading to supply chain vulnerabilities.

Efforts are underway to develop sustainable alternatives and recycling methods to address these challenges.

The Future of Rare Earth Magnets

As industries like renewable energy and electric vehicles continue to grow, the demand for rare earth magnets will only increase. Innovations in magnet materials and manufacturing processes are expected to further enhance their performance and sustainability.

Key Takeaways

- Rare Earth Magnets are the strongest permanent magnets available, offering unparalleled magnetic strength and versatility.

- Neodymium magnets are ideal for compact applications requiring high performance, while samarium cobalt magnets excel in high-temperature environments.

- Applications range from automotive and wind power to consumer electronics and medical devices.

- Challenges like environmental impact and supply chain issues highlight the need for sustainable solutions.

For more information on customizing magnets for specific industries, explore Customized NdFeB Magnets.

This article provides an in-depth overview of rare earth permanent magnets, their types, applications, and significance in today’s world. If you’re looking for custom neodymium magnets for your specific needs, feel free to contact us.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.