Permanent Magnet Materials for High-Performance Applications

In this comprehensive guide, we’ll explore the different types of permanent magnet materials, their properties, and their applications. Whether you’re designing an electric motor, working on renewable energy systems, or simply curious about the science behind magnets, this article will provide valuable insights to help you make informed decisions.

Table of Contents

What Are Permanent Magnet Materials?

Permanent magnet materials are substances that can retain their magnetic properties even after the removal of an external magnetic field. Unlike temporary magnets, which lose their magnetism when the external field is removed, permanent magnets maintain their magnetism indefinitely under normal conditions.These materials are made from ferromagnetic materials, which have unique atomic structures that allow their magnetic domains to align and stay aligned. Common examples of permanent magnet materials include:

- Neodymium (NdFeB): Known for their incredible strength and versatility.

- Samarium cobalt (SmCo): Ideal for high-temperature and corrosive environments.

- Ferrite magnets: Cost-effective and widely used in everyday applications.

- Alnico magnets: Known for their stability and resistance to demagnetization.

Each type of material has unique properties that make it suitable for specific applications, which we’ll explore in detail below.

Why Are Permanent Magnet Materials Important?

Permanent magnets are critical in modern technology because they provide a stable and reliable source of magnetism. This makes them indispensable in applications such as:

- Electric motors: Used in everything from household appliances to electric vehicles.

- Renewable energy: Essential in wind turbines and other green technologies.

- Medical devices: Used in MRI machines and other diagnostic tools.

- Consumer electronics: Found in speakers, headphones, and hard drives.

Without permanent magnets, many of the technologies we rely on today would not be possible.

What Are the Types of Permanent Magnet Materials?

1. Neodymium Iron Boron (NdFeB) Magnets

Neodymium magnets, also known as NdFeB magnets, are the strongest permanent magnets available. They are made from an alloy of neodymium, iron, and boron

, and are known for their high magnetic strength and compact size.Key features:

- High magnetic energy: Provides exceptional strength in a small volume.

- Versatility: Available in various shapes and sizes, including magnet assemblies.

- Applications: Used in electric motors, wind turbines, and consumer electronics.

However, neodymium magnets are prone to corrosion and may require protective coatings for certain applications.

2. Samarium Cobalt (SmCo) Magnets

Samarium cobalt magnets are known for their excellent performance in extreme conditions. They are made from an alloy of samarium and cobalt, which gives them unique properties.Key features:

- High temperature resistance: Can withstand temperatures up to 300°C.

- Corrosion resistance: Ideal for harsh environments.

- Applications: Used in aerospace, automotive, and industrial equipment.

While SmCo magnets are not as strong as neodymium magnets, their stability and durability make them a popular choice for demanding applications.

3. Ferrite Magnets

Ferrite magnets, also known as ceramic magnets, are made from a mixture of iron oxide and barium or strontium carbonate. They are the most cost-effective type of permanent magnet.Key features:

- Low cost: Affordable and widely available.

- Corrosion resistance: Naturally resistant to rust.

- Applications: Used in speakers, motors, and household appliances.

Although ferrite magnets are not as strong as rare earth magnets, their affordability makes them a practical choice for many applications.

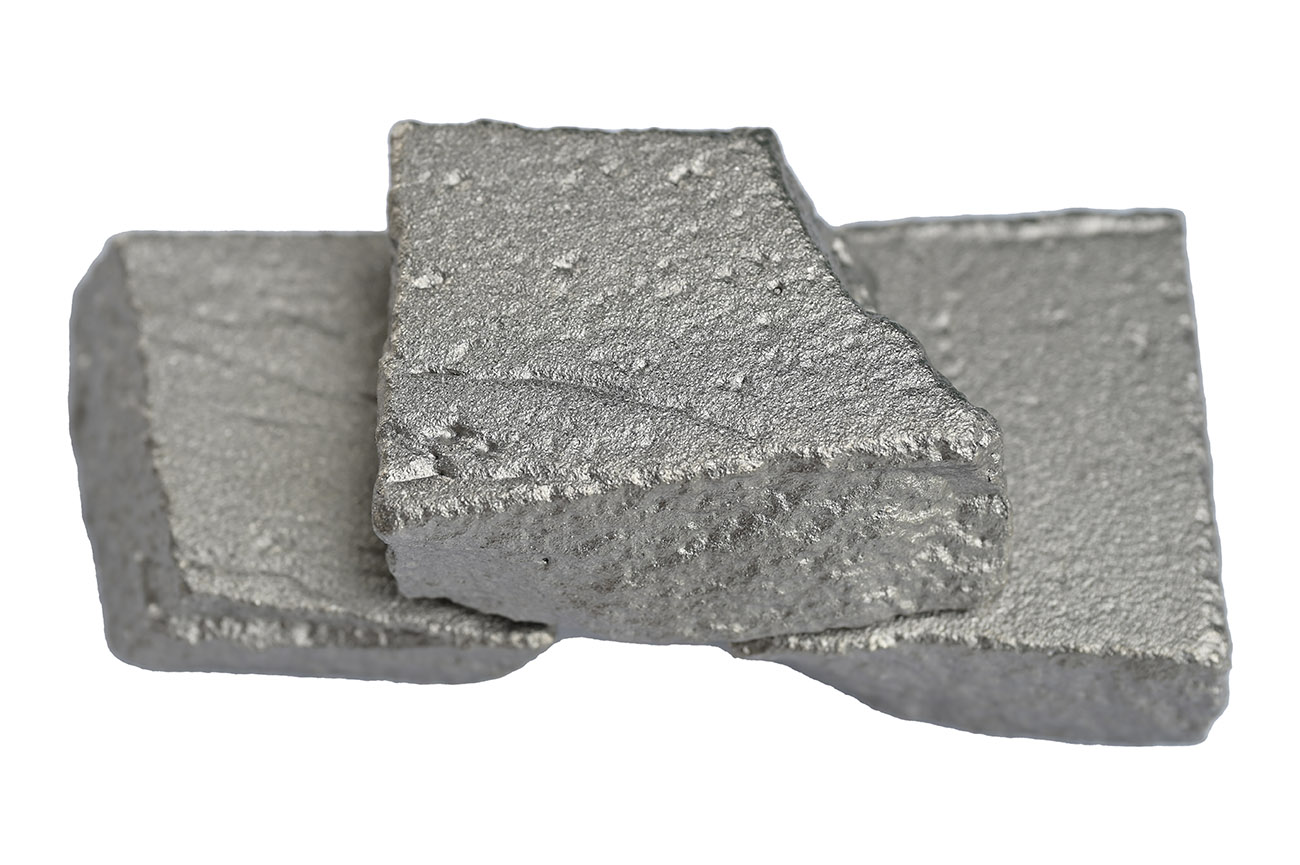

4. Alnico Magnets

Alnico magnets are made from an alloy of aluminum, nickel, and cobalt. They are known for their stability and resistance to demagnetization.Key features:

- High stability: Retains magnetism over time.

- Temperature resistance: Performs well in high-temperature environments.

- Applications: Used in sensors, instruments, and industrial equipment.

While alnico magnets are not as strong as neodymium or SmCo magnets, their reliability makes them a valuable option for specific applications.

How Are Permanent Magnets Made?

The manufacturing process for permanent magnets involves several steps:

- Material preparation: The raw materials are melted and alloyed to create the desired composition.

- Powdering and pressing: The alloy is ground into a fine powder and pressed into the desired shape.

- Sintering: The pressed material is heated to fuse the particles together.

- Magnetizing: The final product is exposed to a strong magnetic field to align the magnetic domains.

This process ensures that the magnets achieve their maximum magnetic performance and durability.

What Are the Applications of Permanent Magnet Materials?

Permanent magnets are used in a wide range of industries due to their unique properties. Here are some of their most common applications:

1. Electric Motors

Permanent magnets are essential in electric motors, where they provide the magnetic field needed to generate motion. Applications include:

- Household appliances: Found in washing machines, refrigerators, and fans.

- Electric vehicles: Used in motors and powertrains.

- Industrial equipment: Essential in servo motors and automation systems.

2. Renewable Energy

The renewable energy sector relies heavily on permanent magnets for their efficiency and reliability. Applications include:

- Wind turbines: Use NdFeB magnets in their generators to convert wind energy into electricity.

- Tidal and wave energy generators: Depend on permanent magnets for power generation.

3. Medical Devices

Permanent magnets play a critical role in medical technology, where precision and reliability are paramount. Examples include:

- MRI machines: Use powerful magnets to create detailed images of the body.

- Surgical tools: Incorporate magnets for enhanced functionality.

4. Consumer Electronics

Permanent magnets are found in many everyday devices, such as:

- Speakers and headphones: Provide clear and powerful sound.

- Hard drives: Enable data storage and retrieval.

- Mobile devices: Used in vibration motors and wireless charging systems.

5. Aerospace and Automotive

In aerospace and automotive applications, permanent magnets are used in:

- Jet engines: Provide stability and performance in extreme conditions.

- Electric propulsion systems: Essential in modern aircraft and spacecraft.

How to Choose the Right Permanent Magnet Material

When selecting a permanent magnet material, consider the following factors:

1. Magnetic Strength

The strength of a magnet is measured in terms of its magnetic energy and grade. For example:

- NdFeB magnets: Offer the highest magnetic strength.

- Ferrite magnets: Provide moderate strength at a lower cost.

2. Temperature Resistance

If your application involves high temperatures, consider using SmCo magnets, which can withstand extreme heat without losing their magnetism.

3. Corrosion Resistance

For environments with high humidity or exposure to chemicals, choose magnets with natural or coated corrosion resistance, such as SmCo or ferrite magnets.

4. Cost and Availability

Consider the cost and availability of the material. While neodymium magnets are the strongest, ferrite magnets are more affordable for large-scale applications.

Are Permanent Magnets Safe?

While permanent magnets are incredibly useful, they must be handled with care due to their strength. Here are some safety tips:

- Avoid pinching: Strong magnets can snap together and cause injuries.

- Keep away from electronics: Magnets can damage sensitive devices like credit cards and pacemakers.

- Store safely: Keep magnets in a secure location to prevent accidents.

Where to Find High-Quality Permanent Magnet Materials

If you’re looking for high-quality permanent magnets, it’s important to choose a reliable supplier. At NdFeB Magnets Factory, we offer a wide range of customized NdFeB magnets for various industries. Whether you need neodymium magnets for electric motors or SmCo magnets for high-temperature applications, we have the right product for you.Explore our collection of customized neodymium magnets to find the perfect solution for your needs.

Conclusion: The Importance of Permanent Magnet Materials

Permanent magnet materials are a cornerstone of modern technology, offering unparalleled strength and versatility. From powering renewable energy systems to enabling advanced medical devices, these materials are indispensable in countless applications.

Key Takeaways:

- NdFeB magnets are the strongest and most versatile permanent magnets.

- SmCo magnets are ideal for high-temperature and corrosive environments.

- Ferrite magnets are cost-effective and widely used in everyday applications.

- Choose the right magnet material based on factors like strength, temperature resistance, and cost.

For more information on permanent magnet materials and their applications, visit our NdFeB Magnets Factory or [contact us](https://neodymiummagnets-factory.com

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.