Motor Magnets: How They Drive Modern Technology

This guide explores the different types of motor magnets, their applications, and their key advantages. Whether you’re an engineer, a manufacturer, or an enthusiast, this article provides actionable insights to help you make informed decisions about motor magnets.

Table of Contents

What Are Motor Magnets?

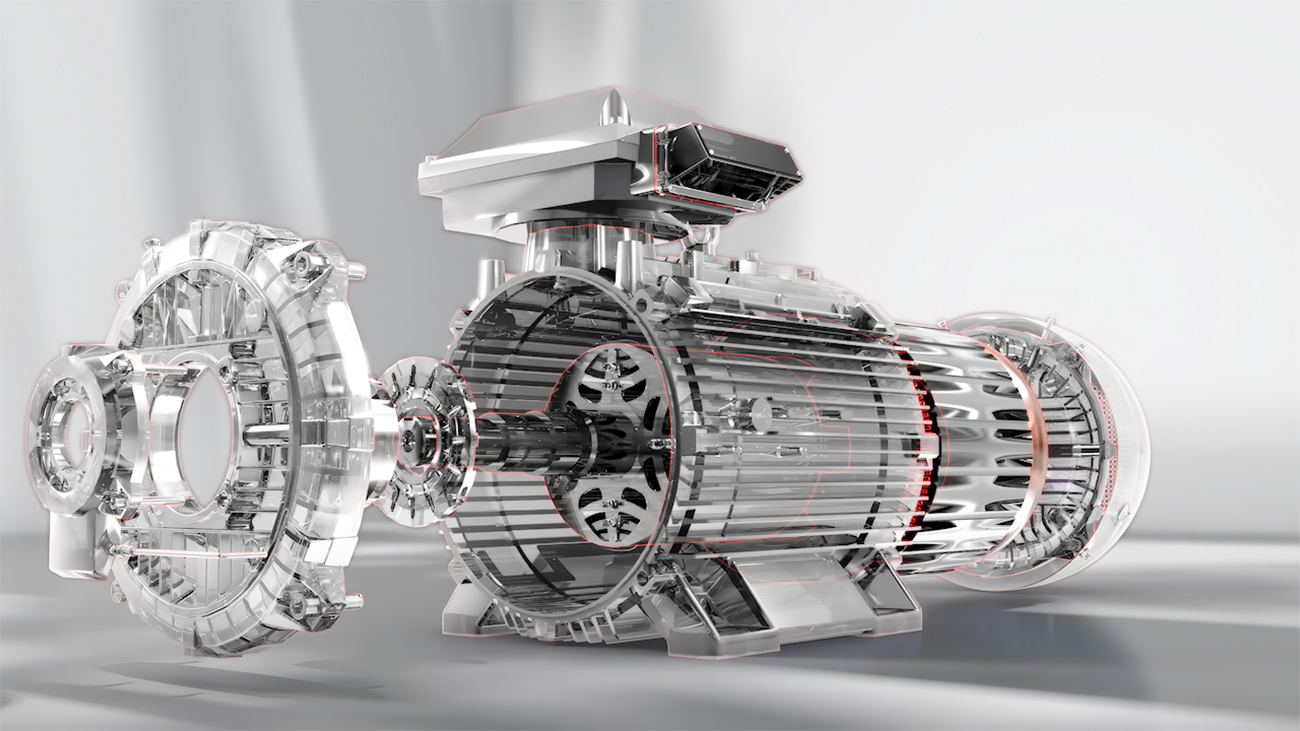

Motor magnets are specialized magnets used in motors to create rotational motion. They generate magnetic fields that interact with the motor’s stator and rotor, producing torque to drive mechanical systems. These magnets are essential in both electric motors and generators, enabling the conversion of electric energy into mechanical energy and vice versa.

Importance of Motor Magnets

Motor magnets determine the efficiency, torque, and overall performance of motors. They are used in a wide range of industries, including automotive, aerospace, renewable energy, and industrial equipment. Advancements in magnet materials like neodymium magnets and samarium cobalt magnets have revolutionized motor design, allowing for lighter, more powerful, and energy-efficient motors.

Types of Motor Magnets

Motor magnets are classified based on their composition and magnetic properties. The most common types include:

| Magnet Type | Composition | Strength | Applications |

| NdFeB (Neodymium) | Neodymium, iron, boron | Strongest | EVs, wind turbines, industrial motors |

| Samarium Cobalt (SmCo) | Samarium, cobalt | High | Aerospace, defense, high-temperature applications |

| Ferrite Magnets | Iron oxide with barium or strontium | Moderate | Household appliances, cost-sensitive areas |

| Alnico Magnets | Aluminum, nickel, cobalt alloy | Medium | Sensors, electric guitars, motors |

| Ceramic Magnets | Ferrite subclass | Low to moderate | Automotive, small motors |

Why Neodymium Magnets Dominate

Neodymium magnets are the strongest permanent magnets available, offering unmatched magnetic strength and versatility. They are widely used in brushless DC motors, electric vehicles, and industrial machinery due to their compact size and high performance.For customized neodymium solutions, explore our Custom NdFeB Magnets.

How Do Motor Magnets Work?

Motor magnets generate a magnetic field that interacts with the stator and rotor in a motor. This interaction produces torque, which drives the motor’s rotation. Here’s a simple breakdown:

- Stator: Fixed magnetic components that provide a stationary magnetic field.

- Rotor: Rotating part of the motor that interacts with the stator’s magnetic field to produce motion.

- Magnetic Field: Created by the motor magnets, enabling the motor to operate efficiently.

What Are Permanent Magnet Motors?

Permanent magnet motors use magnets that maintain their magnetic properties over time, without requiring external power to generate a magnetic field. These motors are highly efficient and are commonly used in applications like electric vehicles, wind turbines, and industrial equipment.

Advantages of Permanent Magnet Motors

- Energy Efficiency: No external power is needed for magnetization.

- Compact Design: Smaller, lighter motors with higher power density.

- High Torque: Ideal for demanding applications like electric vehicles and renewable energy systems.

To learn more about permanent magnet motors, visit our NdFeB Magnets Factory.

Neodymium Magnets in Motors: Why They Excel

Neodymium magnets (NdFeB) have become the go-to choice for motor designs due to their exceptional magnetic properties. They offer high magnetic strength, making them two to three times stronger than ferrite magnets.

Key Features of Neodymium Magnets

- High Magnetic Strength: Ideal for compact, high-performance motors.

- Corrosion Resistance: Coatings like nickel plating protect against wear and tear.

- Wide Operating Temperatures: Can withstand temperatures up to 220°C with specialized grades.

For more on Neodymium Magnets in Motors, visit our Customized NdFeB Magnets.

Samarium Cobalt vs. Neodymium Magnets: Which Is Better?

Both samarium cobalt magnets (SmCo) and neodymium magnets are excellent choices for high-performance motors, but they have distinct advantages.

Samarium Cobalt Magnets

- High Temperature Resistance: Operates up to 350°C, making them suitable for aerospace and defense systems.

- Corrosion Resistance: Naturally resistant to corrosion, no coating required.

Neodymium Magnets

- Stronger Magnetic Field: Offers the highest magnetic strength available.

- Cost-Effective: More affordable than SmCo for most applications.

For extreme conditions, SmCo magnets are the better choice. For general high-performance motors, neodymium magnets dominate.

Applications of Motor Magnets

Motor magnets are used in diverse industries, enabling advanced technologies. Here are some key applications:

Automotive

- Electric Vehicles (EVs): Utilize NdFeB magnets for compact, high-torque motors.

- Hybrid Vehicles: Rely on permanent magnet motors for energy efficiency.

Learn more about NdFeB for the Automotive Industry.

Renewable Energy

- Wind Turbines: Use powerful neodymium magnets for efficient energy conversion.

- Generators: Employ motor magnets to produce electricity.

Explore our Magnets in Wind Power.

Industrial Equipment

- Servo Motors: Require arc magnets for precise motion control.

- Industrial Motors: Use NdFeB magnets for high durability and performance.

Visit our Custom NdFeB Magnets for Industrial Equipment.

Why Choose Arc Magnets for Motors?

Arc magnets are specifically designed for motors, providing a curved shape that fits perfectly around the rotor. This ensures optimal magnetic force and reduces magnetic losses.

Benefits of Arc Magnets

- High Magnetic Strength: Ideal for high-performance motors.

- Customizable Shapes: Tailored to specific motor designs.

- Durability: Resistant to wear, ensuring long-term performance.

For more information, check out our Customized NdFeB Arc Magnets.

Brushless DC Motors: A Revolution in Motor Design

Brushless DC motors (BLDC) rely on permanent magnets to eliminate the need for brushes, resulting in lower maintenance and higher efficiency.

Advantages of Brushless DC Motors

- Energy Efficiency: No power loss due to brushes.

- Durability: Longer lifespan compared to brushed motors.

- Quiet Operation: Ideal for noise-sensitive applications like medical devices and household appliances.

To explore more, visit our Custom NdFeB Magnets for BLDC Motors.

How to Choose the Right Motor Magnet Supplier

Choosing the right motor magnet supplier is critical for ensuring high-quality products and reliable performance.

Factors to Consider

- Material Quality: Ensure the supplier offers high-grade NdFeB or SmCo magnets.

- Customization Options: Look for suppliers who can tailor magnets to your specific motor design.

- Experience and Expertise: Partner with a supplier with proven expertise in motor magnet applications.

For premium magnets, contact us at NdFeB Magnets Factory.

Key Takeaways

- Motor magnets are essential for powering modern technologies, from EVs to industrial equipment.

- Neodymium magnets are the strongest and most versatile, dominating motor applications.

- Samarium cobalt magnets excel in high-temperature and corrosion-resistant environments.

- Advances like arc magnets and brushless DC motors are driving innovation in motor design.

- Choosing the right magnet type and supplier is key to ensuring high performance and durability.

For custom solutions, explore our Customized NdFeB Magnets and Motor Magnet Applications.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.