High-Performance NdFeB Magnets for Custom Automotive Powertrain Systems

As demand for efficient and sustainable vehicles grows, manufacturers increasingly rely on these powerful magnets to meet performance and environmental standards.

This article dives deep into the world of NdFeB magnets in custom automotive powertrain systems, examining their applications, advantages, and future innovations. Whether you’re an automotive engineer, parts supplier, or curious reader, this comprehensive guide will explain why NdFeB magnets are indispensable in modern vehicles.

Table of Contents

What Are NdFeB Magnets and How Do They Work in Automotive Powertrain Systems?

NdFeB magnets—short for neodymium iron boron magnets—are among the strongest rare earth magnets available today. Their superior magnetic properties make them ideal for demanding applications like powertrain systems in vehicles. But what sets them apart?These permanent magnets generate a strong magnetic field by aligning the electrons in their neodymium, iron, and boron alloy. This powerful magnetic force is harnessed in electric motors, rotors, and other powertrain components to deliver high torque, smooth propulsion, and energy efficiency.In the automotive industry, NdFeB magnets are used to optimize motor performance, reduce vehicle weight, and meet increasing energy demands. Their ability to operate reliably at high RPMs and under extreme conditions makes them indispensable in modern powertrain systems.

Why Are NdFeB Magnets the Preferred Choice for Powertrain Components?

NdFeB magnets stand out among other magnetic materials due to their unmatched combination of magnetic strength, durability, and versatility. Here’s why they dominate in powertrain components:

- High Magnetic Strength: NdFeB magnets provide superior flux density, enabling smaller motors with higher performance.

- Compact Size: These magnets can deliver strong magnetic force without adding unnecessary weight, aiding in weight reduction for vehicles.

- Durability: With proper coatings, NdFeB magnets resist corrosion and maintain their performance under harsh conditions.

- Cost-Effective: Compared to alternatives like samarium cobalt (SmCo) magnets, NdFeB offers better value for most automotive applications.

For manufacturers seeking to optimize motor efficiency and energy use, NdFeB magnets are the go-to solution.

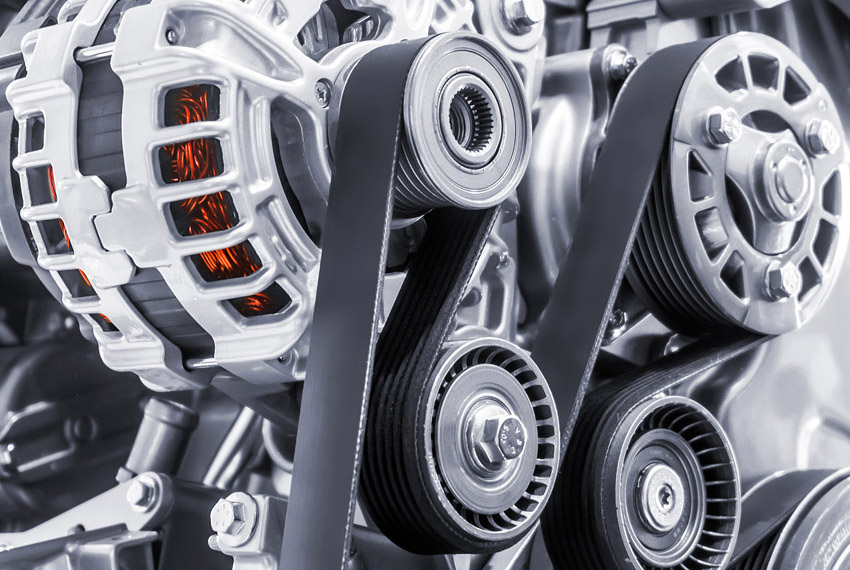

Key Applications of NdFeB Magnets in Automotive Powertrain Systems

NdFeB magnets are integral to a wide range of powertrain components, including:

- Electric Motors: Powering everything from propulsion systems in electric vehicles (EVs) to auxiliary systems like water pumps.

- Actuators: Delivering precise motion control in torque converters and other mechanical systems.

- Sensors: Ensuring accurate measurement in systems like position and speed sensors.

- Rotors and Stators: Used in rotational assemblies for generating consistent power output.

These applications highlight how NdFeB magnets are critical to achieving high-performance, energy-efficient vehicles.

What Are the Benefits of Using Neodymium Magnets in Electric Motors?

Electric motors are the backbone of modern powertrain systems, and neodymium magnets are at their core. Here are the key benefits of using NdFeB magnets in electric motors:

- Enhanced Motor Efficiency: By reducing energy loss, these magnets optimize the energy conversion process, improving overall system efficiency.

- High Torque Output: The strong magnetic field they produce allows motors to deliver higher torque at lower RPMs.

- Compact Design: NdFeB magnets enable smaller, lighter motors without compromising on power.

These advantages are particularly important in EVs, where energy use and driving experience are top priorities.

The Role of NdFeB Magnets in Hybrid and Electric Vehicle Powertrains

Hybrid and electric vehicles (EVs) rely heavily on NdFeB magnets to achieve their performance and efficiency goals. Here’s how they contribute:

- In Propulsion Systems: NdFeB magnets drive the electric motors that power EVs and assist combustion engines in hybrids.

- In Regenerative Braking: They play a crucial role in capturing energy during braking and converting it into usable electricity.

- In Energy Management: NdFeB magnets are used in systems that balance power delivery between the motor, battery, and other components.

By enabling lighter, more efficient designs, these magnets are paving the way for sustainable transportation.

Customizing NdFeB Magnets for Specific Powertrain Applications

Every powertrain system has unique requirements, and custom NdFeB magnets are designed to meet these challenges. Customization options include:

- Shape and Size: Tailored to fit compact motor assemblies or specific rotors and stators.

- Coatings: Protective layers like nickel or epoxy to enhance durability and resist corrosion.

- Grades: Different grades of magnets (e.g., N42, N50) offer varying levels of performance to match application needs.

Learn more about custom NdFeB magnets here.

NdFeB Magnets vs. SmCo Magnets: Which Is Better for Automotive?

While NdFeB magnets are the most commonly used, SmCo (samarium cobalt) magnets are another option for automotive applications. Here’s how they compare:

While SmCo magnets are better suited for high-temperature environments, NdFeB magnets are the preferred choice for most powertrain components due to their superior performance and cost-effectiveness.

Addressing Corrosion and High-Temperature Challenges in NdFeB Magnets

NdFeB magnets can face challenges like corrosion and loss of performance at higher temperatures. To overcome these, manufacturers use:

- Protective Coatings: Materials like nickel or epoxy to shield magnets from moisture and oxidation.

- High-Temperature Grades: Specialized grades like N35UH or N42SH are engineered to withstand operating temperatures above 150°C.

These innovations ensure that NdFeB magnets remain reliable even in demanding vehicle applications.

How NdFeB Magnets Enhance Energy Efficiency in Vehicles

One of the primary reasons manufacturers choose NdFeB magnets is their ability to improve energy efficiency. Here’s how:

- Reducing Energy Loss: NdFeB magnets minimize inefficiencies in power conversion, leading to better motor efficiency.

- Weight Reduction: By enabling smaller, lighter designs, they reduce the overall weight of the vehicle, enhancing fuel or battery efficiency.

- Optimized Performance: Their high magnetic strength ensures peak performance without compromising energy use.

These benefits make NdFeB magnets essential for achieving environmentally friendly and cost-effective designs.

The Future of NdFeB Magnets in Automotive Powertrain Systems

As the automotive industry evolves, NdFeB magnets will continue to play a crucial role in advancing powertrain systems. Key trends include:

- Increased Adoption in EVs: As EVs become mainstream, demand for NdFeB magnets will grow exponentially.

- Advancements in Materials: Research into rare-earth alloys and coatings will further enhance durability and performance.

- Sustainability: Efforts to recycle rare-earth materials and reduce environmental impact will shape future manufacturing practices.

The versatility and power of NdFeB magnets ensure

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.