High-Performance NdFeB Magnets for Aerospace Engines and Electric Propulsion Systems

These rare-earth magnets are indispensable in modern aerospace technologies, particularly in aerospace engines and electric propulsion systems, where high efficiency, precision, and reliability are paramount. This article explores the unique properties of NdFeB magnets, their customization capabilities, and their critical role in aerospace applications.Whether you’re a professional in the aerospace industry, an engineer designing propulsion systems, or simply someone curious about the high-tech world of magnets, this article provides valuable insights into how customized NdFeB magnets are driving innovation in flight and space exploration.

Table of Contents

What Are NdFeB Magnets and Why Are They Special?

NdFeB (neodymium-iron-boron) magnets are rare earth magnets known for their exceptional magnetic properties. They are the strongest permanent magnets available today, offering unmatched magnetic strength and energy efficiency.Their advantages include:

- High magnetic power: Ideal for compact, lightweight designs.

- Resistance to demagnetization: Ensures durability in challenging environments.

- Wide temperature range: Custom grades can operate in extreme conditions.

In aerospace applications, these characteristics make NdFeB magnets indispensable for precise and reliable performance.

How Are NdFeB Magnets Used in Aerospace Applications?

The aerospace industry relies heavily on NdFeB magnets for various uses, including:

- Electric propulsion systems: Providing the driving force behind ion and Hall-effect thrusters.

- Flight control systems: Enhancing the performance of actuators and other components.

- Magnetic sensors: Offering precise feedback for navigation and control.

These magnets play a pivotal role in ensuring the efficiency and reliability of aerospace engines and other critical systems. Their versatility and high performance make them suitable for a variety of applications, including military and commercial aviation.

Why Choose Custom NdFeB Magnets for Electric Propulsion Systems?

Customization is key when it comes to meeting the specific demands of electric propulsion systems. Off-the-shelf magnets may not offer the precise specifications and performance required for advanced aerospace technologies.

Benefits of Custom NdFeB Magnets:

- Tailored magnetic assemblies: Designed to fit unique propulsion system requirements.

- Enhanced magnetic properties: Optimized strength, durability, and temperature resistance.

- Compliance with aerospace standards: Fully compliant with DFARS and ITAR regulations.

For example, customized NdFeB magnets are specifically engineered to meet the challenges of space environments, from radiation exposure to extreme temperatures.

Key Properties of High-Performance NdFeB Magnets

1. Magnetic Strength

NdFeB magnets offer the highest energy product among all permanent magnets, making them ideal for compact and lightweight aerospace designs.

2. Temperature Resistance

Special grades, such as N52 and N50M, maintain their magnetic properties even at elevated temperatures, ensuring reliability in propulsion systems.

3. Corrosion Resistance

Coatings like nickel or epoxy protect against corrosion, extending the lifespan of the magnets in harsh environments.

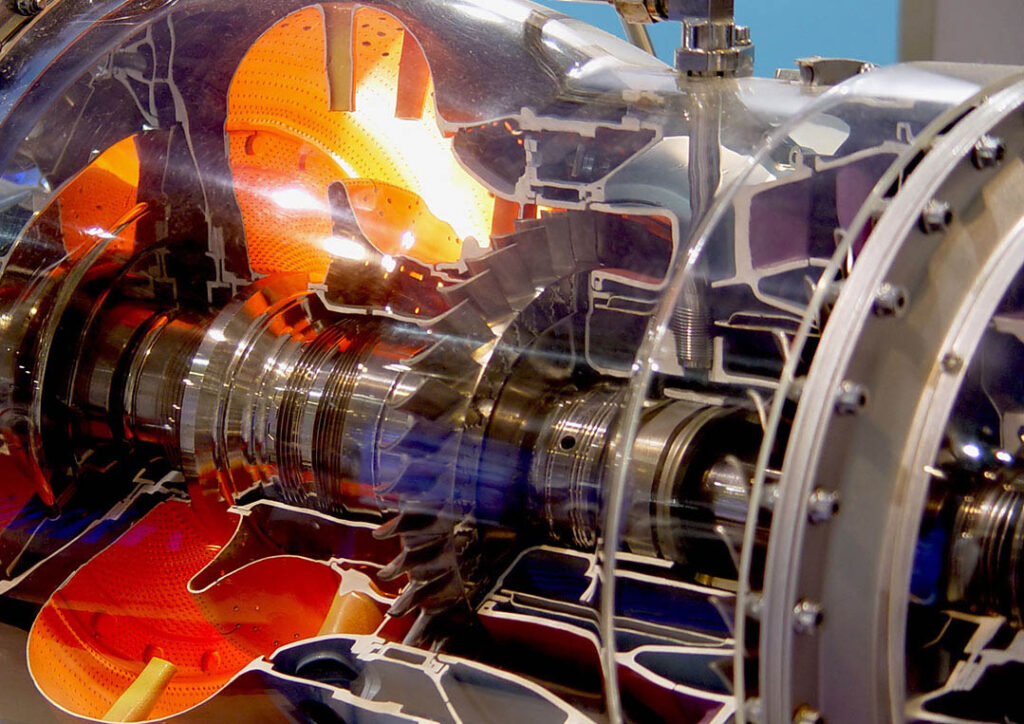

Aerospace Engines: The Role of NdFeB Magnets

Magnetic Rotor Assemblies

Magnetic rotors in aerospace engines rely on high-performance NdFeB magnets for efficient power generation and reduced weight.

Brushless DC Motors

Brushless DC motors, which are essential in aerospace applications, use NdFeB magnets for their superior torque and efficiency.

“NdFeB magnets are now indispensable in aerospace engines, offering the highest energy product and unmatched magnetic strength.”

Learn more about customized neodymium magnets for aerospace.

Electric Propulsion Systems: Powered by Rare Earth Magnets

Electric propulsion systems in satellites and spacecraft depend on NdFeB magnets for high thrust-to-weight ratios and precision control.

Applications Include:

- Hall-effect thrusters: Using NdFeB magnets for precise magnetic field control.

- Ion propulsion systems: Reliant on rare-earth permanent magnets for efficiency.

These systems benefit from the strong magnetic field and high durability of NdFeB magnets, ensuring long-term performance in space.

Customization: Meeting Aerospace Industry Demands

The aerospace industry demands precision, reliability, and performance. Customizing NdFeB magnets allows manufacturers to meet these requirements.

Customization Options:

- Magnet grades: Choose from a wide range of grades, such as N40H, N42SH, and N50M.

- Magnetic assemblies: Tailored solutions for specific aerospace applications.

- Design and manufacturing: Advanced capabilities to optimize mechanical design.

For example, customized NdFeB magnets offer unparalleled flexibility for aerospace engineers.

NdFeB Magnet Grades for Aerospace Applications

Different grades of NdFeB magnets provide unique advantages for aerospace applications. Some common grades include:

| Grade | Max Temp (°C) | Applications |

| N42 | 80 | General-purpose aerospace components |

| N50M | 100 | High-temperature propulsion systems |

| N42SH | 150 | Extreme conditions in space environments |

Explore more about NdFeB magnet grades.

How to Ensure Compliance With Aerospace Standards

Compliance is critical in the aerospace industry. NdFeB magnets must meet strict regulations, including:

- DFARS compliance: Ensuring materials are sourced responsibly.

- ITAR regulations: Meeting national defense standards.

- Resistance to demagnetization: Critical for reliable performance.

For fully compliant solutions, contact specialists who can tailor your NdFeB magnets to meet these requirements.

Contacting Specialists for Custom NdFeB Magnet Solutions

Need a solution for your aerospace project? Contact a specialist to discuss your specific requirements. With expertise in design and manufacturing, they can provide tailored customized NdFeB magnets for your application.Visit our aerospace solutions page to get started. We’ll get back to you within 24 hours.

Key Takeaways

- NdFeB magnets are the strongest permanent magnets, making them ideal for aerospace engines and electric propulsion systems.

- Customization ensures these magnets meet the specific demands of the aerospace industry, from high temperatures to extreme durability.

- Compliance with aerospace standards, such as DFARS and ITAR, is essential for reliable performance.

- Contacting specialists ensures you get tailored solutions for your unique requirements.

For more information, explore our custom NdFeB magnet solutions.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.