Force Magnet: Exploring the Magnetic Force and Its Applications

From household applications to advanced industrial uses, understanding the pull force and magnetic field of magnets can help you choose the right magnet for your specific needs and maximize its potential.

Table of Contents

Why Read This Article?

This article dives deep into the science of magnetic force, explaining how magnets work, the factors that affect their strength, and their practical applications in industries like automotive, aerospace, and electronics. Whether you’re a student, a professional, or simply curious about magnets, this guide will provide you with everything you need to know about the force of magnets and how to select the right magnet for any application.

What is the Magnetic Force?

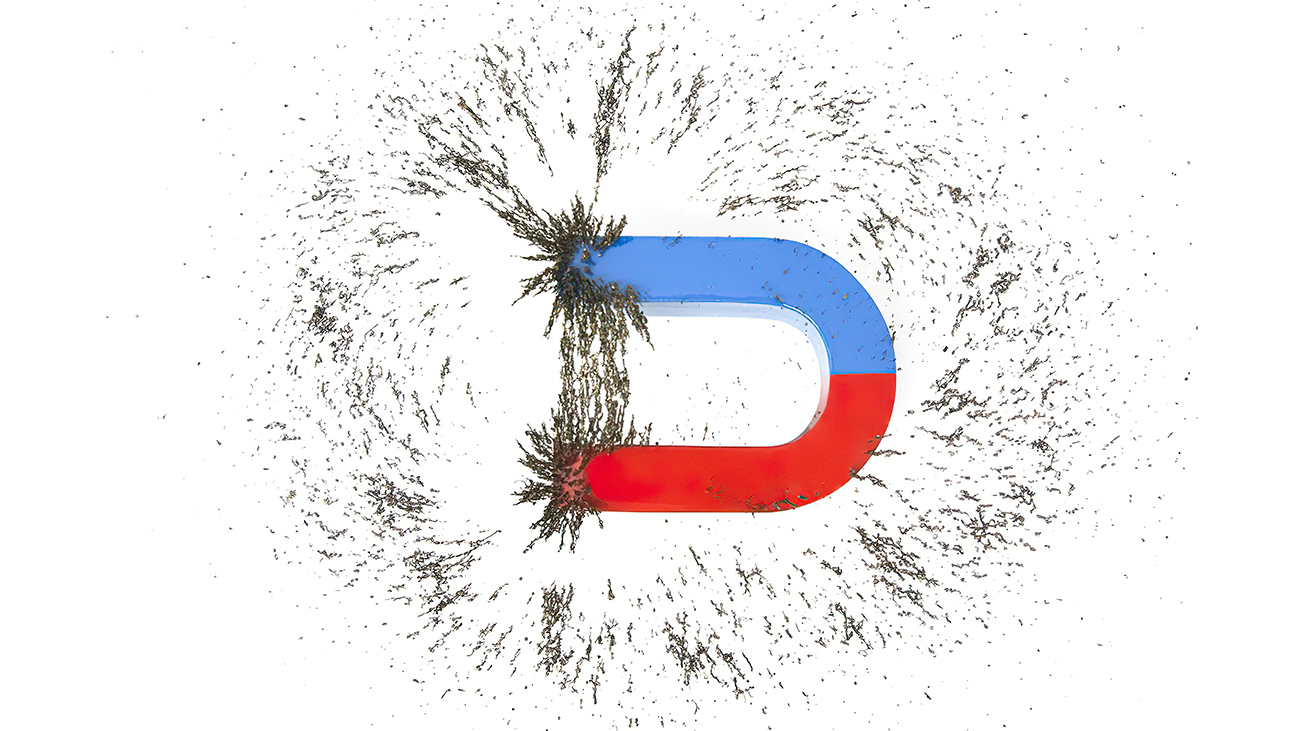

The magnetic force is the attraction or repulsion that occurs between magnetic materials, such as iron, cobalt, or nickel. It is caused by the movement of electric charges within the atoms of these materials, creating a magnetic field that exerts a force on other objects.

How Does the Magnetic Force Work?

The magnetic force works through the interaction of magnetic field lines, which flow from a magnet’s north pole to its south pole. When two magnets are brought close to each other:

- Like poles (e.g., north-north or south-south) repel each other.

- Opposite poles (e.g., north-south) attract each other.

This force depends on several factors, including the strength of the magnetic field, the distance between the magnets, and the type of material they interact with.

Factors That Determine the Strength of a Magnet

The strength of a magnet depends on various factors, which play a crucial role in determining its pull force and overall performance.

1. Material Composition

- Neodymium magnets, also known as rare earth magnets, are some of the strongest magnets available today. They are made from neodymium, iron, and boron, offering unparalleled magnetic strength.

- Other magnets, like alnico magnets, are made from aluminum, nickel, and cobalt, and are less powerful.

2. Size and Shape of the Magnet

The size and shape of a magnet affect its magnetic field and concentration of force. For example:

- Disc magnets provide a concentrated magnetic pull on their flat sides.

- Ring magnets are useful for applications requiring a central hole for mounting.

3. Distance and Air Gap

The magnetic force decreases as the distance between two magnets increases. Similarly, an air gap or a non-magnetic barrier between magnets reduces the strength of the magnetic interaction.

How Pull Force is Measured

The pull force of a magnet refers to the maximum force it can exert to hold or attract an object. It is measured in kilograms (kg) or pounds, depending on the system of measurement.

Pull Force Testing

To determine the pull force of a magnet, a controlled test is conducted where the magnet is placed on a flat steel plate, and the force required to pull it away is measured. This test provides insight into the magnet’s holding power and strength.Tip: Always consider the contact surface and roughness of the material when testing pull force, as these factors significantly affect the results.

Types of Magnets and Their Magnetic Force

Magnets come in various types, each with unique properties and applications.

1. Neodymium Magnets

- Neodymium magnets are the strongest permanent magnets available.

- They are widely used in industries like automotive, aerospace, and electronics due to their high magnetic field strength and compact size.

2. Ferrite Magnets

- Also known as ceramic magnets, ferrite magnets are more affordable but less powerful than neodymium magnets.

- They are commonly used in household appliances and toys.

3. Alnico Magnets

- Made from aluminum, nickel, and cobalt, alnico magnets excel in high-temperature applications.

- They are often used in industrial equipment and audio devices.

For more information on customized neodymium magnets, visit Customized NdFeB Magnets.

How to Choose the Right Magnet

Selecting the right magnet for your application involves considering several factors:

1. Application Requirements

- For high-strength applications, such as electric motors or wind turbines, neodymium magnets are ideal.

- For general-purpose use, ferrite magnets or alnico magnets may suffice.

2. Contact Area and Surface Conditions

The contact area between the magnet and the object affects its performance. Ensure the surface is clean and flat to maximize the magnet’s holding power.

3. Environmental Conditions

- High temperatures can weaken the magnet’s strength. For such conditions, choose magnets with coatings or materials designed for heat resistance.

- To learn more about selecting the right magnet coatings, check out Custom Magnet Coatings.

Applications of Magnetic Force

The magnetic force is utilized in a wide range of industries and applications:

1. Automotive Industry

Magnets play a crucial role in electric motors, sensors, and powertrain systems. For more information, explore NdFeB for the Automotive Industry.

2. Aerospace Components

Magnets are used in electric propulsion systems and other critical aerospace components. Learn more at Custom Aerospace Magnets.

3. Wind Power Generation

Permanent magnets are essential for wind turbines, enabling renewable energy systems. Visit Wind Power Magnets to learn more.

4. Medical Devices

Magnets are used in MRI machines and other medical devices. For more details, check out Magnets for Medical Devices.

Frequently Asked Questions (FAQs)

Q1: What is the pull force of a magnet?

The pull force is the maximum force a magnet can exert to attract or hold an object. It depends on the magnet’s material, size, and the contact surface.

Q2: How do neodymium magnets compare to ferrite magnets?

Neodymium magnets are significantly stronger and more compact than ferrite magnets, making them ideal for high-performance applications. However, ferrite magnets are more cost-effective and resistant to corrosion.

Q3: Can magnets lose their strength?

Yes, magnets can lose their strength due to factors like high temperatures, physical damage, or exposure to demagnetizing fields.

Conclusion

The force of magnets is a fascinating phenomenon that has countless applications in modern life. Understanding the factors that influence a magnet’s strength and selecting the right type of magnet for your needs can significantly enhance the efficiency of your projects.

Key Takeaways:

- Magnetic force is the attraction or repulsion between magnets or magnetic materials.

- Factors like material composition, size, and surface conditions affect a magnet’s pull force.

- Neodymium magnets are the strongest magnets available and are widely used in industries like automotive, aerospace, and renewable energy.

- Choosing the right magnet requires careful consideration of the application, contact surface, and environmental conditions.

For more information on customized magnets, visit Customized NdFeB Magnets, NdFeB Magnets for Automotive Applications, or Wind Power Magnets.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.