Ferrite Magnets: Exploring Their Pros and Cons Across Industries

This article takes a closer look at the magnetic properties of ferrite magnets, their manufacturing process, and their applications across industries. By understanding their strengths and weaknesses, you can determine whether ferrite magnets are the right choice for your specific needs.

Table of Contents

What Are Ferrite Magnets?

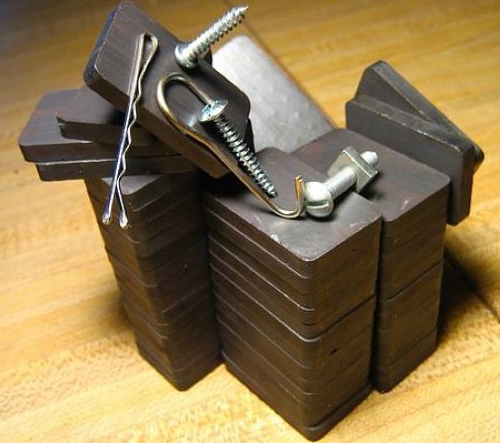

Ferrite magnets are a type of permanent magnet made primarily from a combination of iron oxide, barium ferrite, or strontium ferrite. These magnets are ceramic in nature, making them cost-effective and resistant to environmental factors like moisture and oxidation.

Key Characteristics of Ferrite Magnets:

- Magnetic Properties: Ferrite magnets exhibit moderate magnetic strength, making them suitable for applications that don’t require extreme power.

- Corrosion Resistance: The ceramic structure of ferrite magnets gives them a natural resistance to rust and corrosion, even in damp environments.

- Affordability: Compared to rare earth magnets like neodymium magnets, ferrite magnets are much more affordable to produce.

These magnets are widely used in applications where cost efficiency and durability outweigh the need for high magnetic strength.

How Are Ferrite Magnets Made?

The manufacturing process of ferrite magnets involves several stages, from raw material preparation to sintering and magnetization.

Ferrite Magnet Manufacturing Process:

- Raw Material Preparation: A mixture of iron oxide and either barium or strontium carbonates is prepared.

- Pressing and Sintering: The raw materials are pressed into molds and then heated at high temperatures to create a solid ceramic structure.

- Magnetization: The resulting ferrite material is exposed to a strong magnetic field, aligning the magnetic domains and creating a permanent magnet.

This process is cost-effective and results in durable magnets with high resistance to demagnetization.

What Are the Advantages of Ferrite Magnets?

Ferrite magnets offer several benefits that make them an attractive choice for a variety of applications.

Key Advantages of Ferrite Magnets:

- Cost-Effective: Ferrite magnets are less expensive to produce compared to neodymium magnets and other rare earth magnets.

- Durability: Their ceramic composition makes them highly resistant to corrosion and suitable for outdoor use.

- High Temperature Resistance: Ferrite magnets can operate in environments with high temperatures, maintaining their magnetic properties up to their Curie temperature.

These attributes make ferrite magnets ideal for applications such as electric motors, speakers, and refrigerator magnets.

What Are the Limitations of Ferrite Magnets?

Despite their advantages, ferrite magnets have some drawbacks that can limit their use in certain applications.

Key Disadvantages of Ferrite Magnets:

- Lower Magnetic Strength: Compared to neodymium magnets, ferrite magnets have a relatively lower magnetic strength, which may not be sufficient for high-performance applications.

- Brittleness: The ceramic nature of ferrite magnets makes them brittle and prone to cracking under mechanical stress.

- Limited Applications: Due to their lower magnetic strength, ferrite magnets are not suitable for applications requiring extremely strong fields.

These limitations must be considered when choosing the right magnet type for your needs.

How Do Ferrite Magnets Compare to Neodymium Magnets?

A common question when selecting magnets is how ferrite magnets compare to neodymium magnets (NdFeB magnets).

Ferrite Magnets vs. Neodymium Magnets:

| Feature | Ferrite Magnets | Neodymium Magnets |

| Magnetic Strength | Moderate | Extremely High |

| Cost | Low | High |

| Corrosion Resistance | Naturally resistant | Requires protective coatings |

| Temperature Resistance | High | Moderate |

| Durability | Brittle | Durable with proper coatings |

While neodymium magnets are ideal for high-performance applications, ferrite magnets are better suited for cost-sensitive projects that don’t require extreme magnetic strength.For more on neodymium magnets, check out Customized NdFeB Magnets.

What Are the Applications of Ferrite Magnets?

Ferrite magnets are used in a wide range of industries due to their versatility and affordability.

Common Applications of Ferrite Magnets:

- Consumer Electronics: Ferrite magnets are used in devices like speakers, televisions, and small motors.

- Automotive: These magnets are found in car starters, electric motors, and door locks.

- Industrial Equipment: Ferrite magnets play a crucial role in machinery like generators and servo motors.

- Household Appliances: From refrigerators to washing machines, ferrite magnets are an integral part of many appliances.

Their durability and cost efficiency make ferrite magnets a reliable choice for these various industries.

Why Are Ferrite Magnets Widely Used in Electric Motors?

Ferrite magnets are a popular choice for electric motors due to their ability to withstand high temperatures and their affordability.

Benefits of Ferrite Magnets in Electric Motors:

- High Temperature Resistance: Ferrite magnets can operate in the high-heat environments of electric motors without losing their magnetic properties.

- Cost Efficiency: Their low production costs make them ideal for large-scale manufacturing.

While neodymium magnets are often used in high-performance motors, ferrite magnets remain a cost-effective alternative for standard applications.

How Do Ferrite Magnets Perform in High-Temperature Environments?

One of the standout features of ferrite magnets is their ability to perform well in high-temperature conditions.

High-Temperature Advantages:

- Ferrite magnets have a high Curie temperature, allowing them to maintain their magnetism at temperatures up to 250°C.

- This makes them suitable for applications like automotive engines and industrial machinery.

Their resistance to demagnetization further enhances their reliability in challenging environments.

What Are the Types of Permanent Magnets, and Where Do Ferrite Magnets Fit?

Ferrite magnets are just one type of permanent magnet, alongside neodymium magnets, samarium cobalt magnets, and alnico magnets.

Types of Permanent Magnets:

- Ferrite Magnets: Affordable and durable, but with moderate magnetic strength.

- Neodymium Magnets: The strongest permanent magnets, but more expensive and prone to corrosion.

- Samarium Cobalt Magnets: High resistance to heat and corrosion, but costly.

- Alnico Magnets: Excellent temperature stability but lower magnetic strength compared to neodymium.

Each type of magnet has its own strengths and weaknesses, making it important to select the right magnet for your application.

Are Ferrite Magnets Eco-Friendly?

Ferrite magnets are considered an environmentally friendly option due to their composition and manufacturing process.

Eco-Friendly Features:

- Abundant Materials: Ferrite magnets are made from materials like iron oxide, which are readily available and non-toxic.

- Low Environmental Impact: The production process for ferrite magnets generates less waste compared to rare earth magnets.

This makes ferrite magnets a sustainable choice for industries looking to reduce their environmental footprint.

Summary: Key Takeaways About Ferrite Magnets

- Ferrite magnets are cost-effective, durable, and resistant to corrosion, making them suitable for a variety of applications.

- They are widely used in industries such as automotive, consumer electronics, and industrial equipment.

- While they have a lower magnetic strength than neodymium magnets, they excel in high-temperature environments and applications requiring affordability.

- The manufacturing process of ferrite magnets involves pressing and sintering ceramic materials, resulting in a durable and eco-friendly product.

- Choosing between ferrite and other permanent magnets depends on the specific requirements of your application.

For applications requiring customized neodymium magnets, visit Customized NdFeB Magnets.

Ferrite magnets may not be the strongest permanent magnets, but their unique combination of affordability, durability, and versatility makes them a reliable choice for many industries. By understanding their advantages and disadvantages, you can make informed decisions for your specific needs.

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.