Elevating Industrial Equipment Performance with Custom NdFeB Magnets

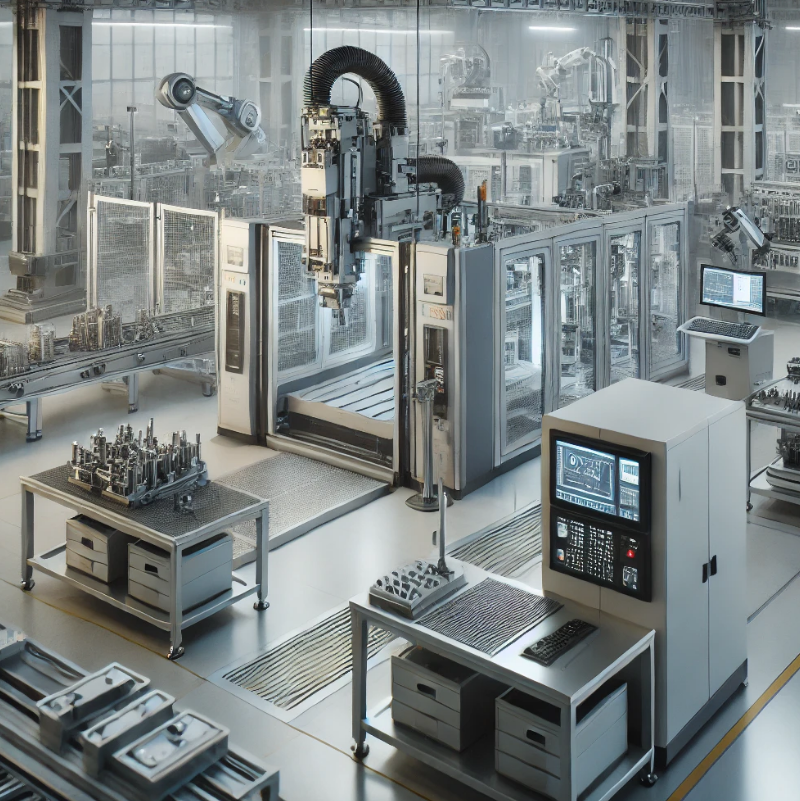

These magnets are critical for industrial applications that demand precision, efficiency, and durability. Whether you’re optimizing motors, sensors, or magnetic assemblies, NdFeB magnets are a game-changer.

This article explores their properties, applications, customization potential, and why NdFeB magnets are the ideal choice for industrial equipment. Read on to discover how these magnetic marvels can transform your machinery.

Table of Contents

What Are NdFeB Magnets?

NdFeB magnets (neodymium iron boron magnets) belong to the rare-earth magnet family and are renowned for their high magnetic strength. These permanent magnets are made from a combination of neodymium, iron, and boron, resulting in exceptional performance that meets the demands of industrial equipment.

Key Characteristics of NdFeB Magnets:

- Strong Magnetic Fields: They have the highest energy product among all magnets, up to 52 MGOe.

- Compact and Lightweight: Their power allows for smaller, more efficient designs in industrial applications.

- Customizability: Available in various shapes, sizes, coatings, and grades to meet specific needs.

Why Are NdFeB Magnets Vital for Industrial Equipment?

Industrial equipment often requires powerful, reliable, and efficient magnetic solutions to ensure optimal performance. NdFeB magnets excel in this domain, offering a balance of strength, durability, and customization.

Benefits for Industrial Applications:

- High Magnetic Strength: Essential for heavy-duty operations like motors, sensors, and actuators.

- Durability: Resistant to demagnetization and wear when properly coated.

- Versatility: Suitable for a wide range of industrial machinery, from robotics to energy-efficient motors.

Industrial applications demand magnets with exceptional magnetic properties, and NdFeB magnets outperform alternatives like ferrite or AlNiCo in most use cases.

How Are Neodymium Magnets Made?

NdFeB magnets are manufactured through a process called sintering, which involves compressing magnetic powders into a dense, solid structure. The result is a robust magnet with superior magnetic properties.

The Sintering Process:

- Powder Preparation: Neodymium, iron, and boron are combined to form a fine powder.

- Compression: The powder is pressed into molds to achieve the desired shape and size.

- Heat Treatment: The compressed material is sintered at high temperatures to enhance its strength and magnetic alignment.

This process ensures that magnets are anisotropic, meaning they are magnetized along a specific axis for optimized performance.

What Are the Benefits of Sintered NdFeB Magnets?

Sintered NdFeB magnets offer several advantages over other magnetic materials, making them indispensable for industrial equipment.

| Feature | NdFeB Magnets | Ferrite Magnets | AlNiCo Magnets |

| Magnetic Strength | Very High | Moderate | High |

| Temperature Resistance | Moderate to High | High | Very High |

| Resistance to Demagnetization | Excellent | Moderate | Moderate |

| Cost | Moderate | Low | High |

Why Use Sintered NdFeB Magnets?

- Superior Magnetic Strength: Ideal for applications requiring compact but powerful components.

- Customizability: Can be tailored to specific industrial needs, including plating and magnetization direction.

Applications of Custom Neodymium Magnets in Industrial Equipment

Custom neodymium magnets are widely used in industrial machinery due to their strength and adaptability. Here are some common applications:

1. Motors and Generators

NdFeB magnets are used in electric motors and generators for their high magnetic strength and efficiency. They enable compact designs while delivering high torque and power.

2. Sensors and Actuators

Industrial sensors rely on NdFeB magnets for precise measurements and control. These components are crucial in automation, robotics, and manufacturing.

3. Magnetic Separation

In industries like mining and recycling, NdFeB magnets are used in magnetic separation to extract or sort materials efficiently.For more details on custom NdFeB magnets for industrial applications, visit Customized NdFeB Magnets.

How to Customize NdFeB Magnets for Specific Industrial Needs

Customizing NdFeB magnets ensures they meet the unique demands of industrial equipment. From magnet grade to coatings, customization options are extensive.

Customization Options:

- Magnet Grade: Choose from grades like N35, N42, or N52 based on your application’s magnetic strength and temperature requirements.

- Coatings: Protect magnets from corrosion with nickel, epoxy, or zinc plating.

- Shapes and Sizes: Tailor the magnet’s dimensions to fit specific machinery designs.

For inquiries about custom shapes, sizes, and grades, explore Custom Neodymium Magnets.

Understanding Magnet Coatings and Corrosion Resistance

NdFeB magnets are prone to corrosion, especially in humid environments. To enhance their durability, coatings are applied during manufacturing.

Common Coating Options:

- Nickel: Provides a smooth, corrosion-resistant finish.

- Epoxy: Offers added protection against moisture and chemicals.

- Zinc: A cost-effective option for basic corrosion resistance.

Proper coating ensures your magnets perform reliably in harsh industrial environments.

NdFeB Magnets vs. Cobalt Magnets: Which Is Better?

Both NdFeB and cobalt magnets are rare-earth magnets, but they excel in different areas. Here’s a comparison:

| Feature | NdFeB Magnets | Cobalt Magnets |

| Magnetic Strength | Higher | Moderate |

| Temperature Resistance | Moderate | Very High |

| Cost | Moderate | Higher |

For most industrial applications, NdFeB magnets are preferred due to their superior magnetic strength and cost-effectiveness.

Grades of Neodymium Magnets: Which One Should You Choose?

NdFeB magnets are available in various grades, such as N35, N42, and N52. Each grade offers unique magnetic properties suitable for different applications.

Grade Overview:

- N35: Cost-effective with moderate strength.

- N42: Balanced performance for general industrial use.

- N52: Maximum magnetic strength for demanding applications.

Learn more about magnet grades at NdFeB Magnet Grades.

Future Trends in NdFeB Magnet Manufacturing

The future of NdFeB magnets is focused on innovation and sustainability. Here are some emerging trends:

- Higher Temperature Resistance: Developing grades that withstand extreme operating temperatures.

- Recycling Rare Earth Materials: Efforts to reduce reliance on raw materials through recycling.

- Advanced Coatings: Enhancing durability and corrosion resistance.

These innovations will further cement NdFeB magnets as the best choice for industrial equipment.

Key Takeaways

- NdFeB magnets are the strongest permanent magnets available, making them essential for industrial equipment.

- They offer unmatched magnetic strength, durability, and customization options.

- Applications range from motors and sensors to magnetic separation systems.

- Proper coatings like nickel or epoxy protect magnets from corrosion in harsh

Welcome to our factory’s custom NdFeB magnet services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards.

You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Economic Development Zone, Industrial Park, Shehong City, Sichuan Province, China.

Contact

News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.