Customized Neodymium Magnets According to Characteristics

Welcome to our factory’s custom NdFeB for Automotive services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards. You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Submit Your Requirements

Our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

Of course! You are always welcome to visit us. Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. We have a friendly and professional team ready to assist you throughout your visit to make sure you have a great experience.

We are a factory! Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. When you order neodymium magnets from us, you work directly with our factory. This means there are no middlemen, which helps save costs, reduce risks, and ensure a safer and more efficient process for you.

Of course! To save your valuable time and ensure the sample matches your product perfectly, we kindly ask you to provide the specifications, drawings, or a sample of your product. Once we have this information, we will produce and send you the sample. We also allow mixed samples.

Our factory has a professional design team and advanced production equipment, which helps us keep costs low and provide you with high-quality magnets at very competitive prices.

First, decide the shape and size of the magnets that best suit your application. Then, visit our webpages “Customized NdFeB Magnets” and “Customized NdFeB Magnets according to Characteristics” to determine the material and grade of the magnets you need.

The next step is to go to the Quotation Request page and fill out the form with details about the magnets and the quantity you require. After clicking the “Submit” button, we will receive your request and provide you with a price quotation.

You can also contact us directly by sending your specifications and drawings.

General manager: Annie Wu

Tel: +86 18926353690

E-mail: [email protected]

It usually takes 1-3 working days. At the same time, we will assign dedicated technical staff and a business manager to your project to provide full support, including technical assistance and follow-up services.

We’re sorry, but from our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

It usually takes 2-3 weeks. If a mold needs to be made, it may take longer. For large quantity orders, such as ten thousand pieces, it may take 3-5 weeks.

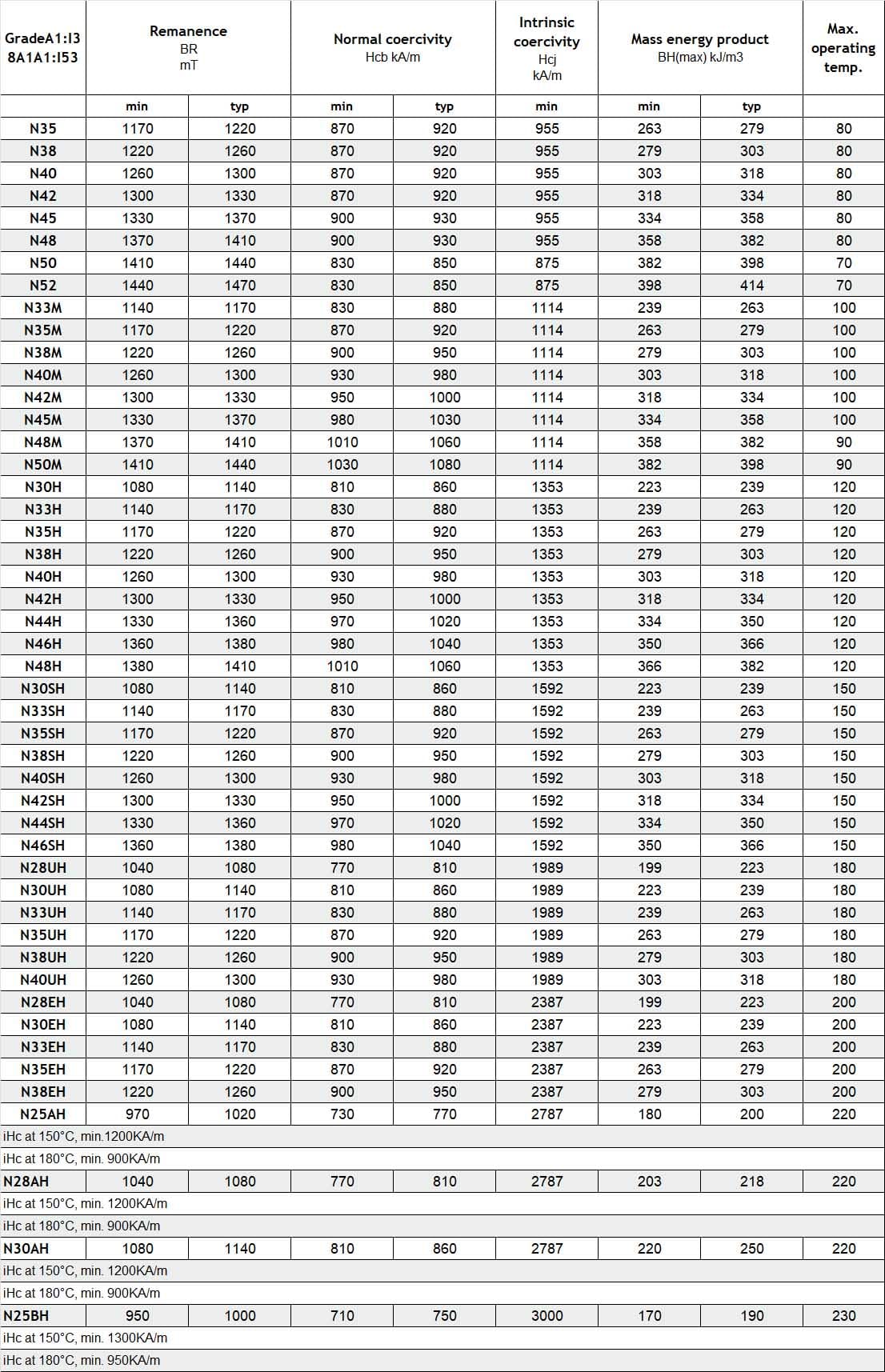

Customized Neodymium Magnets(NdfeB) Data Sheet

The grading system for Neodymium magnets(NdFeB) follows a straightforward nomenclature, beginning with “N” for “Neo” followed by a two-digit number. Higher numbers indicate stronger magnetic properties, allowing you to select the perfect grade for your specific application.

| Grade | Remanence BR mT | Normal coercivity Hcb kA/m | Intrinsic coercivity Hcj kA/m | Mass energy product BH(max) kJ/m3 | Max operating temp | |||

| min | typ | min | typ | min | min | typ | ||

| N35 | 1170 | 1220 | 870 | 920 | 955 | 263 | 279 | 80 |

| N38 | 1220 | 1260 | 870 | 920 | 955 | 279 | 303 | 80 |

| N40 | 1260 | 1300 | 870 | 920 | 955 | 303 | 318 | 80 |

| N42 | 1300 | 1330 | 870 | 920 | 955 | 318 | 334 | 80 |

| N45 | 1330 | 1370 | 900 | 930 | 955 | 334 | 358 | 80 |

| N48 | 1370 | 1410 | 900 | 930 | 955 | 358 | 382 | 80 |

| N50 | 1410 | 1440 | 830 | 850 | 875 | 382 | 398 | 70 |

| N52 | 1440 | 1470 | 830 | 850 | 875 | 398 | 414 | 70 |

| N33M | 1140 | 1170 | 830 | 880 | 1114 | 239 | 263 | 100 |

| N35M | 1170 | 1220 | 870 | 920 | 1114 | 263 | 279 | 100 |

| N38M | 1220 | 1260 | 900 | 950 | 1114 | 279 | 303 | 100 |

| N40M | 1260 | 1300 | 930 | 980 | 1114 | 303 | 318 | 100 |

| N42M | 1300 | 1330 | 950 | 1000 | 1114 | 318 | 334 | 100 |

| N45M | 1330 | 1370 | 980 | 1030 | 1114 | 334 | 358 | 100 |

| N48M | 1370 | 1410 | 1010 | 1060 | 1114 | 358 | 382 | 90 |

| N50M | 1410 | 1440 | 1030 | 1080 | 1114 | 382 | 398 | 90 |

| N30H | 1080 | 1140 | 810 | 860 | 1353 | 223 | 239 | 120 |

| N33H | 1140 | 1170 | 830 | 880 | 1353 | 239 | 263 | 120 |

| N35H | 1170 | 1220 | 870 | 920 | 1353 | 263 | 279 | 120 |

| N38H | 1220 | 1260 | 900 | 950 | 1353 | 279 | 303 | 120 |

| N40H | 1260 | 1300 | 930 | 980 | 1353 | 303 | 318 | 120 |

| N42H | 1300 | 1330 | 950 | 1000 | 1353 | 318 | 334 | 120 |

| N44H | 1330 | 1360 | 970 | 1020 | 1353 | 334 | 350 | 120 |

| N46H | 1360 | 1380 | 980 | 1040 | 1353 | 350 | 366 | 120 |

| N48H | 1380 | 1410 | 1010 | 1060 | 1353 | 366 | 382 | 120 |

| N30SH | 1080 | 1140 | 810 | 860 | 1592 | 223 | 239 | 150 |

| N33SH | 1140 | 1170 | 830 | 880 | 1592 | 239 | 263 | 150 |

| N35SH | 1170 | 1220 | 870 | 920 | 1592 | 263 | 279 | 150 |

| N38SH | 1220 | 1260 | 900 | 950 | 1592 | 279 | 303 | 150 |

| N40SH | 1260 | 1300 | 930 | 980 | 1592 | 303 | 318 | 150 |

| N42SH | 1300 | 1330 | 950 | 1000 | 1592 | 318 | 334 | 150 |

| N44SH | 1330 | 1360 | 970 | 1020 | 1592 | 334 | 350 | 150 |

| N46SH | 1360 | 1380 | 980 | 1040 | 1592 | 350 | 366 | 150 |

| N28UH | 1040 | 1080 | 770 | 810 | 1989 | 199 | 223 | 180 |

| N30UH | 1080 | 1140 | 810 | 860 | 1989 | 223 | 239 | 180 |

| N33UH | 1140 | 1170 | 830 | 880 | 1989 | 239 | 263 | 180 |

| N35UH | 1170 | 1220 | 870 | 920 | 1989 | 263 | 279 | 180 |

| N38UH | 1220 | 1260 | 900 | 950 | 1989 | 279 | 303 | 180 |

| N40UH | 1260 | 1300 | 930 | 980 | 1989 | 303 | 318 | 180 |

| N28EH | 1040 | 1080 | 770 | 810 | 2387 | 199 | 223 | 200 |

| N30EH | 1080 | 1140 | 810 | 860 | 2387 | 223 | 239 | 200 |

| N33EH | 1140 | 1170 | 830 | 880 | 2387 | 239 | 263 | 200 |

| N35EH | 1170 | 1220 | 870 | 920 | 2387 | 263 | 279 | 200 |

| N38EH | 1220 | 1260 | 900 | 950 | 2387 | 279 | 303 | 200 |

| N25AH | 970 | 1020 | 730 | 770 | 2787 | 180 | 200 | 220 |

| iHc at 150°C, min.1200KA/m | ||||||||

| iHc at 180°C, min. 900KA/m | ||||||||

| N28AH | 1040 | 1080 | 770 | 810 | 2787 | 203 | 218 | 220 |

| iHc at 150°C, min. 1200KA/m | ||||||||

| iHc at 180°C, min. 900KA/m | ||||||||

| N30AH | 1080 | 1140 | 810 | 860 | 2787 | 220 | 250 | 220 |

| iHc at 150°C, min. 1200KA/m | ||||||||

| iHc at 180°C, min. 900KA/m | ||||||||

| N25BH | 950 | 1000 | 710 | 750 | 3000 | 170 | 190 | 230 |

| iHc at 150°C, min. 1300KA/m | ||||||||

| iHc at 180°C, min. 950KA/m | ||||||||

Remarks on facing table

- The max working temperature is only for reference, it is dependent on the circuit in

which the magnet is operating. - Customers are advised to consult us on any application involving temperatures near to

150°C. - When L/D = 0.7, the magnet can be operated at maximum working temperature before

irreversable losses occur

Physical properties at room temperature (20°C)

Temp. Coeff. Of Br −0.11%/°C

Density 7.5/cm³

Vickers Hardness 600Hv

Tensile Strength 8.0kg/mm²

Specific Heat 0.12 kcal/(kg,°C)

Young’s Modulus 1.6 × 10¹¹N/m²

Poisson’s Ratio 0.24

Curie Temperature 310–340°C

Temp. Coeff of iHc −0.60%/°C

Electrical Resistivity 144 μΩ.cm

Flexural Strength 25kg/mm

Coeff. Of Thermal Expansion 4×10–6/°C

Thermal Conductivity 7.7 kcal/(m.h. °C)

Rigidity 0.64N/m²

Compressibility 9.8 × 10–¹²m²/N

Customized Neodymium Magnets: Tailored Solutions for Every Application

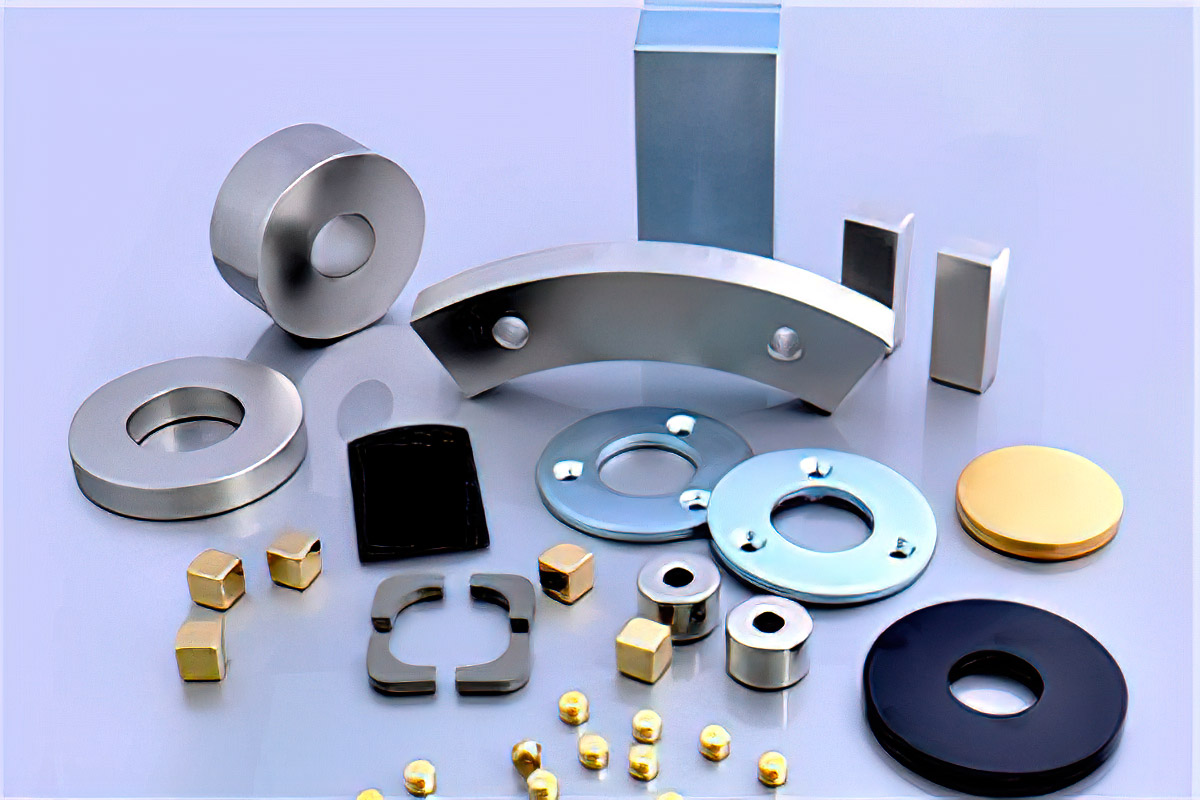

Neodymium magnets, also known as NdFeB magnets, are the strongest and most versatile rare earth magnets available today. These magnets are widely used across industries due to their high magnetic strength, compact size, and ability to be customized for specific applications. Whether you need arc magnets for motors, block magnets for industrial machinery, or uniquely shaped magnets for specialized uses, custom-made neodymium magnets offer unparalleled flexibility and performance.This article will guide you through the process of customizing neodymium magnets, their unique characteristics, and why they are essential for modern applications. If you’re looking to understand how magnets are made, what customization options are available, or how to get a quote for custom magnets, this article is for you.

What Is a Neodymium Magnet?

A neodymium magnet is a permanent magnet made from an alloy of neodymium, iron, and boron. These magnets belong to the rare earth magnet family and are known for their high magnetic strength and durability. Developed in the 1980s, neodymium magnets have become the most widely used type of rare earth permanent magnet due to their superior performance compared to other types of magnets, such as ceramic magnets or alnico magnets. Neodymium magnets are available in various shapes, sizes, and grades, making them suitable for a wide range of applications. Their ability to be customized further enhances their versatility, allowing them to meet the specific needs of industries like automotive, electronics, and renewable energy.

Why Choose Custom Neodymium Magnets?

What Are Custom Neodymium Magnets?

Custom neodymium magnets are magnets that are specifically designed and manufactured to meet unique requirements. Unlike standard magnets, which come in predefined shapes and sizes, custom magnets can be tailored in terms of:

- Shape: Options include arc magnets, block magnets, ring magnets, and more.

- Size: From small magnets for electronics to large neodymium magnets for industrial use.

- Magnetic Properties: Adjusted to provide the desired magnetic force and temperature resistance.

Customization ensures that the magnet fits perfectly into its intended application, maximizing efficiency and performance.

How Are Neodymium Magnets Made?

The process of creating custom neodymium magnets involves several steps:

- Material Preparation: The neodymium iron boron alloy is prepared and melted.

- Sintering: The material is compressed and heated to form a solid structure, creating sintered NdFeB magnets.

- Shaping and Cutting: Magnets are cut into the desired shape, such as arc magnets or block magnets.

- Coating: To enhance durability, magnets are coated with materials like nickel, epoxy, or gold.

This process ensures that the magnets’ magnetic properties are optimized for their specific use.

Customization Options for Neodymium Magnets

What Shapes and Sizes Are Available?

One of the key benefits of custom neodymium magnets is the variety of shapes and sizes available. Common options include:

- Block Magnets: Ideal for industrial applications requiring strong, uniform magnetic fields.

- Arc Magnets: Used in motors and generators to create rotational motion.

- Ring Magnets: Common in sensors, speakers, and medical devices.

- Horseshoe Magnets: Provide focused magnetic fields for specialized applications.

Additionally, special-shaped neodymium magnets can be created to meet unique requirements, such as irregular geometries or complex designs.

What Grades of Neodymium Magnets Are Available?

NdFeB magnets are graded based on their magnetic strength and temperature resistance. Common grades include:

- N35 to N52: Higher numbers indicate stronger magnetic fields.

- H, SH, UH, EH: These grades signify the magnet’s ability to withstand high temperatures.

Choosing the right grade ensures that the magnet performs optimally in its intended environment. For example, N52 magnets are among the strongest available, while SH magnets are designed for high-temperature applications.

What Coating Options Are Available?

To protect against corrosion and wear, neodymium magnets can be coated with various materials, including:

- Nickel: The most common coating, providing a smooth and durable finish.

- Epoxy: Ideal for harsh environments where additional protection is needed.

- Gold or Silver: Often used for medical or decorative purposes.

These coatings enhance the magnets’ longevity and ensure consistent performance over time.

Applications of Custom Neodymium Magnets

Where Are Custom Neodymium Magnets Used?

Neodymium magnets are used in various industries due to their strength and versatility. Common applications include:

- Automotive: Arc magnets are essential for electric motors and rotor assemblies.

- Electronics: Small magnets are used in headphones, sensors, and hard drives.

- Renewable Energy: Wind turbines rely on strong rare earth magnets for efficient energy generation.

- Medical Devices: Neodymium ring magnets are used in MRI machines and surgical tools.

Their ability to be customized makes them indispensable for specialized applications.

What Are the Benefits of Custom Neodymium Magnets?

Custom magnets offer several advantages, including:

- Optimized Performance: Tailored to meet specific requirements, ensuring maximum efficiency.

- Cost Savings: Reduces waste by using only the necessary materials and sizes.

- Versatility: Suitable for a wide range of applications, from industrial machinery to consumer electronics.

Ordering Custom Neodymium Magnets

How to Get a Quote for Custom Magnets?

To get a quote for custom magnets, you’ll need to provide the following details:

- Dimensions: Specify the size and shape of the magnet.

- Magnetic Properties: Indicate the required grade and strength.

- Coating and Finish: Mention any special coatings or finishes needed.

Manufacturers like Stanford Magnets specialize in creating high-quality, custom rare earth magnets and can provide competitive quotes.

What Is the Lead Time for Custom Magnets?

The lead time for custom magnets depends on factors like size, shape, and complexity. In general:

- Standard Shapes: 2-4 weeks.

- Complex Designs: 4-8 weeks.

Working with a reliable manufacturer ensures timely delivery and high-quality results.

Key Considerations for Custom Magnets

What Should You Consider When Ordering Custom Magnets?

Before placing an order, consider the following:

- Application Requirements: What will the magnet be used for?

- Environmental Factors: Will the magnet be exposed to heat, moisture, or chemicals?

- Safety Precautions: Keep magnets away from sensitive electronics or medical devices.

By addressing these factors, you can ensure your custom magnets meet your needs perfectly.

Summary: Key Takeaways

Here are the most important things to remember about custom neodymium magnets:

- Neodymium magnets are the strongest permanent magnets available, offering unmatched magnetic strength.

- Customization allows magnets to be tailored to specific shapes, sizes, and magnetic properties.

- Applications range from industrial and automotive to medical and renewable energy solutions.

- Coatings and grades ensure durability and performance in various environments.

- Our can provide high-quality custom solutions with competitive lead times.

If you need custom magnets, consider reaching out to a trusted manufacturer to explore your options and get started with your project today!

YLSRE is a factory specializing in the production of high-performance neodymium magnets(NdFeB ) for various industries.

More

Need A Quote?

Submit your drawing

Get a free sample

We will respond within 8H of receiving your message.

Industry News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.