Custom NdFeB for Wind Power

Welcome to our factory’s custom NdFeB for Automotive services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards. You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Submit Your Requirements

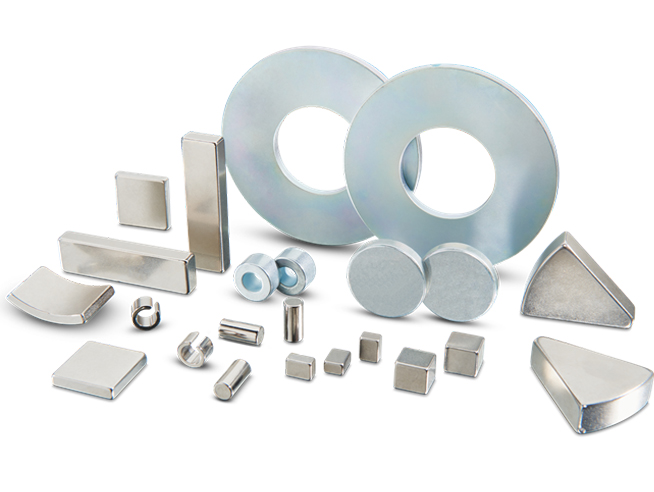

Our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

Of course! You are always welcome to visit us. Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. We have a friendly and professional team ready to assist you throughout your visit to make sure you have a great experience.

We are a factory! Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. When you order neodymium magnets from us, you work directly with our factory. This means there are no middlemen, which helps save costs, reduce risks, and ensure a safer and more efficient process for you.

Of course! To save your valuable time and ensure the sample matches your product perfectly, we kindly ask you to provide the specifications, drawings, or a sample of your product. Once we have this information, we will produce and send you the sample. We also allow mixed samples.

Our factory has a professional design team and advanced production equipment, which helps us keep costs low and provide you with high-quality magnets at very competitive prices.

First, decide the shape and size of the magnets that best suit your application. Then, visit our webpages “Customized NdFeB Magnets” and “Customized NdFeB Magnets according to Characteristics” to determine the material and grade of the magnets you need.

The next step is to go to the Quotation Request page and fill out the form with details about the magnets and the quantity you require. After clicking the “Submit” button, we will receive your request and provide you with a price quotation.

You can also contact us directly by sending your specifications and drawings.

General manager: Annie Wu

Tel: +86 18926353690

E-mail: [email protected]

It usually takes 1-3 working days. At the same time, we will assign dedicated technical staff and a business manager to your project to provide full support, including technical assistance and follow-up services.

We’re sorry, but from our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

It usually takes 2-3 weeks. If a mold needs to be made, it may take longer. For large quantity orders, such as ten thousand pieces, it may take 3-5 weeks.

The Role of NdFeB Magnets in Wind Power Generation: Driving Renewable Energy Forward

Wind power is one of the fastest-growing sources of renewable energy, offering a clean and sustainable alternative to fossil fuels. At the heart of modern wind turbines lies a critical component: NdFeB magnets (neodymium iron boron magnets). These rare earth magnets are essential for the efficiency and reliability of wind turbine generators, enabling the production of electricity from wind with minimal environmental impact.

What Are NdFeB Magnets and Why Are They Important?

NdFeB magnets, or neodymium iron boron magnets, are a type of permanent magnet made from an alloy of neodymium, iron, and boron. These magnets are known for their exceptional magnetic properties, including their ability to generate a strong magnetic field in a compact size. They are widely regarded as the most powerful magnetic material available today.Key Features of NdFeB Magnets:

- High Magnetic Strength: NdFeB magnets produce a powerful magnetic field, making them ideal for high-performance applications.

- Compact and Lightweight: Their strength allows for smaller designs, which is crucial in industries like wind power.

- Durability: These magnets are resistant to demagnetization, ensuring long-term reliability.

How Do Wind Turbines Work?

To understand the role of magnets in wind turbines, it’s essential to first grasp how these machines generate electricity. Wind turbines convert the kinetic energy of wind into electrical energy through a series of steps:- Wind Blades Capture Energy: The blades of a wind turbine rotate when wind flows over them, converting wind’s kinetic energy into mechanical energy.

- Mechanical Energy Drives the Generator: The rotation of the blades turns a shaft connected to a generator.

- Generator Produces Electricity: Inside the generator, magnets and coils of wire interact to produce an electric current.

Why Are Magnets Used in Wind Turbines?

Magnets play a crucial role in the operation of wind turbines, particularly in the generator. The generator is responsible for converting mechanical energy into electricity, and this process depends on the interaction between a magnetic field and conductive materials.Benefits of Using Magnets in Wind Turbines:

- Efficiency: Magnets enable the generator to produce electricity with minimal energy loss.

- Compact Design: The use of rare earth magnets like NdFeB allows for smaller, lighter generators.

- Reliability: Permanent magnets, such as NdFeB magnets, ensure consistent performance over time.

The Role of Permanent Magnets in Wind Power Generation

Permanent magnets, including NdFeB magnets, are a key component of wind turbine generators. Unlike electromagnets, which require an external power source to generate a magnetic field, permanent magnets maintain their magnetism without additional energy input.Why Permanent Magnets Are Ideal for Wind Turbines:

- Energy Efficiency: By eliminating the need for an external power source, permanent magnets reduce energy consumption.

- Durability: These magnets are built to withstand the demanding conditions of wind farms, including extreme temperatures and high wind speeds.

- Low Maintenance: The use of permanent magnets reduces the need for regular maintenance, lowering overall costs.

NdFeB Magnets in Wind Turbines: Key Advantages

The use of NdFeB magnets in wind turbines offers several advantages over other types of magnetic materials, such as SmCo magnets or ceramic magnets.Advantages of NdFeB Magnets:

- High Magnetic Energy Product: This property allows for the generation of a strong magnetic field in a compact size.

- Lightweight Design: The reduced weight of NdFeB magnets makes them ideal for direct-drive turbines, which eliminate the need for a gearbox.

- Cost-Effectiveness: Despite their higher initial cost, the efficiency and durability of NdFeB magnets result in lower long-term costs.

Direct-Drive Turbines and the Use of NdFeB Magnets

Direct-drive turbines are a type of wind turbine that uses NdFeB magnets to eliminate the need for a gearbox. This design offers several advantages:- Increased Efficiency: By reducing mechanical losses, direct-drive turbines achieve higher energy conversion rates.

- Lower Maintenance Costs: The absence of a gearbox reduces the need for regular maintenance.

- Improved Reliability: Direct-drive turbines are less prone to mechanical failures, making them ideal for offshore wind farms.

Challenges in the Supply Chain of Rare Earth Magnets

Despite their advantages, the production of NdFeB magnets faces challenges related to the supply chain of rare earth materials. Neodymium and other rare earth elements are primarily mined in a few countries, leading to potential supply constraints.Addressing Supply Chain Challenges:

- Recycling: Recovering rare earth materials from end-of-life products can reduce reliance on mining.

- Substitution: Research into alternative materials may help mitigate supply risks.

- Sustainable Mining Practices: Ensuring ethical and environmentally friendly mining practices is crucial for the long-term availability of rare earth elements.

Recycling and Sustainability of NdFeB Magnets

Recycling NdFeB magnets is an important step toward sustainability in the wind power industry. By recovering rare earth materials from used magnets, manufacturers can reduce waste and lower production costs.Benefits of Recycling NdFeB Magnets:

- Environmental Impact: Recycling reduces the need for mining, minimizing environmental damage.

- Cost Savings: Recycled materials are often cheaper than newly mined resources.

- Supply Chain Stability: Recycling helps ensure a steady supply of rare earth materials.

The Future of NdFeB Magnets in the Wind Power Industry

The future of NdFeB magnets in the wind power industry looks promising. As technology advances, these magnets will continue to play a vital role in improving the efficiency and reliability of wind turbines.Emerging Trends:

- Larger Turbines: The development of larger, more powerful turbines will increase the demand for high-performance NdFeB magnets.

- Offshore Wind Farms: The growth of offshore wind farms will drive innovation in magnet technology to withstand harsh marine environments.

- Sustainable Practices: Efforts to recycle and reduce the environmental impact of magnet production will shape the future of the industry.

How NdFeB Magnets Are Driving the Transition to Clean Energy

NdFeB magnets are a cornerstone of the renewable energy sector, enabling the efficient generation of electricity from wind. Their magnetic properties, durability, and compact design make them indispensable for modern wind turbines.Key Takeaways:

- NdFeB magnets are essential for the operation of wind turbine generators.

- They improve the efficiency, reliability, and sustainability of wind power systems.

- Addressing supply chain challenges and promoting recycling will ensure the continued growth of the wind power industry.

YLSRE is a factory specializing in the production of high-performance neodymium magnets(NdFeB ) for various industries.

More

Need A Quote?

Submit your drawing

Get a free sample

We will respond within 8H of receiving your message.

Industry News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.