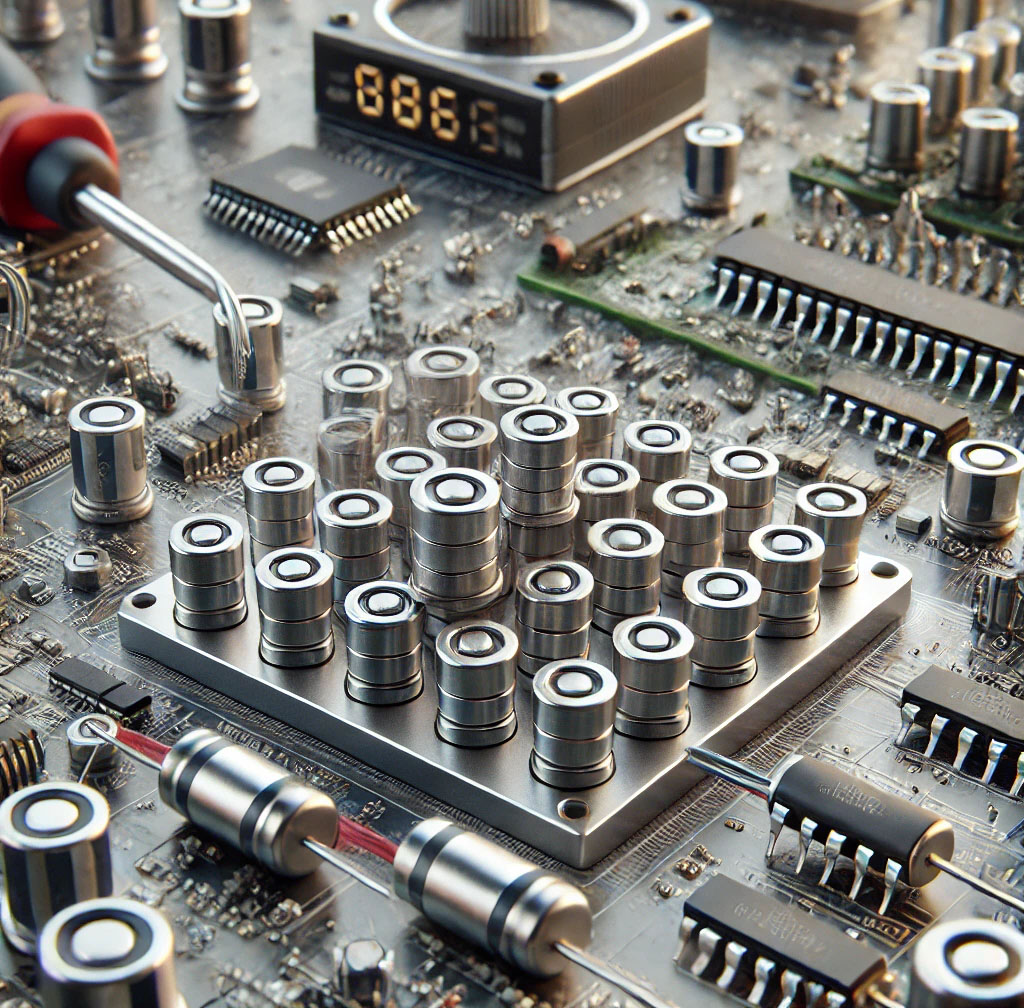

Custom NdFeB for Electronics

Welcome to our factory’s custom NdFeB for Automotive services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards. You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Submit Your Requirements

Our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

Of course! You are always welcome to visit us. Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. We have a friendly and professional team ready to assist you throughout your visit to make sure you have a great experience.

We are a factory! Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. When you order neodymium magnets from us, you work directly with our factory. This means there are no middlemen, which helps save costs, reduce risks, and ensure a safer and more efficient process for you.

Of course! To save your valuable time and ensure the sample matches your product perfectly, we kindly ask you to provide the specifications, drawings, or a sample of your product. Once we have this information, we will produce and send you the sample. We also allow mixed samples.

Our factory has a professional design team and advanced production equipment, which helps us keep costs low and provide you with high-quality magnets at very competitive prices.

First, decide the shape and size of the magnets that best suit your application. Then, visit our webpages “Customized NdFeB Magnets” and “Customized NdFeB Magnets according to Characteristics” to determine the material and grade of the magnets you need.

The next step is to go to the Quotation Request page and fill out the form with details about the magnets and the quantity you require. After clicking the “Submit” button, we will receive your request and provide you with a price quotation.

You can also contact us directly by sending your specifications and drawings.

General manager: Annie Wu

Tel: +86 18926353690

E-mail: [email protected]

It usually takes 1-3 working days. At the same time, we will assign dedicated technical staff and a business manager to your project to provide full support, including technical assistance and follow-up services.

We’re sorry, but from our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

It usually takes 2-3 weeks. If a mold needs to be made, it may take longer. For large quantity orders, such as ten thousand pieces, it may take 3-5 weeks.

The Ultimate Guide to NdFeB Magnets for Electronics: Everything You Need to Know

NdFeB magnets, also known as neodymium magnets or neodymium iron boron magnets, are the strongest type of permanent magnets available today. These magnets are widely used in various industries, especially electronics, due to their exceptional magnetic strength, compact size, and versatility. Whether you’re designing motors, sensors, or consumer electronics, understanding NdFeB magnets is crucial for optimizing performance and efficiency. This article dives deep into everything you need to know about NdFeB magnets, including their properties, applications, and how to customize them for specific needs.

What Are NdFeB Magnets?

NdFeB magnets, short for neodymium iron boron magnets, belong to the rare-earth magnet family. They are super strong rare earth magnets made from an alloy of neodymium, iron, and boron. These magnets are known for their exceptional magnetic strength, making them ideal for applications where strong magnetic fields are required in compact spaces.

Key Features of NdFeB Magnets:

- Strongest permanent magnets available today.

- High magnetic energy and maximum energy product for improved performance.

- Commonly found in industries such as automotive, consumer electronics, and medical devices, including hard disk drives and magnetic resonance imaging (MRI) systems.

NdFeB magnets are also known as sintered neodymium magnets, as they are typically manufactured using the powder metallurgy process.

How Are Neodymium Magnets Manufactured?

The creation of NdFeB magnets begins with the sintering process, a form of powder metallurgy. This technique ensures the magnets achieve their maximum magnetic potential while maintaining a compact size.

Steps in Manufacturing NdFeB Magnets:

- Powder Metallurgy: The raw materials (neodymium, iron, boron, and other alloys) are blended and compacted into a mold.

- Sintering: The compacted powder is heated, causing the particles to fuse and form a solid magnet.

- Magnetization: The material is exposed to a strong magnetic field, aligning the domains to create a powerful magnetic force.

- Coating: To protect the magnet from corrosion, coatings such as epoxy or nickel-plating are applied.

The complexity of the design and the materials used in this process allow for the creation of magnets tailored for specific industries.

Why Are NdFeB Magnets Used in Electronics?

Neodymium magnets are a cornerstone of modern electronics due to their high magnetic strength, compact size, and ability to operate in various conditions.

Common Applications in Electronics:

- Hard Disk Drives (HDDs): Used to create stable magnetic fields for data storage.

- Motors and Generators: Enhance performance and efficiency in devices such as electric vehicles.

- Consumer Electronics: Found in speakers, microphones, and even smartphones for their strong magnetic fields.

- Magnetic Sensors: Used in automotive and industrial applications for precise measurements.

Their ability to provide strong magnetic properties in small sizes is what makes them indispensable for modern devices.

What Are the Key Magnetic Properties of NdFeB Magnets?

The properties of NdFeB magnets define their usability and performance in various applications.

Magnetic Properties:

- Magnetic Strength: NdFeB magnets offer exceptional magnetic strength, making them ideal for applications requiring high performance.

- High Magnetic Energy: The high magnetic energy density allows for compact designs.

- Magnetic Force: These magnets deliver a strong magnetic force, even in small sizes.

Comparison with Other Magnets:

| Property | NdFeB Magnets | Ferrite Magnets | Alnico Magnets |

| Magnetic Strength | Exceptional | Moderate | Moderate |

| Temperature Resistance | Moderate | High | High |

| Cost | Higher | Lower | Moderate |

How Do Coatings Improve NdFeB Magnets?

Since NdFeB magnets are prone to corrosion, applying a protective coating is critical for long-term durability.

Common Coating Materials:

- Nickel-Copper-Nickel (Ni-Cu-Ni): Offers excellent resistance to corrosion.

- Epoxy Coating: Provides protection against moisture, making it ideal for outdoor use.

The choice of coating depends on the application and environmental conditions. For example, epoxy coatings are preferred for marine environments, while nickel plating is commonly used for industrial applications.

What Is the Role of NdFeB Magnets in Motors and Generators?

NdFeB magnets play a crucial role in the efficiency and performance of motors and generators, particularly in electric vehicles and renewable energy systems.

How They Work:

- In motors, NdFeB magnets create a strong magnetic field, improving torque and reducing energy consumption.

- In generators, they convert mechanical energy into electrical energy with high efficiency.

Their ability to maintain strong magnetic fields in compact designs makes them essential for motors and generators in automotive and renewable energy industries.

How to Customize NdFeB Magnets for Specific Applications?

Customizing NdFeB magnets ensures they meet the exact specific needs of a project.

Customization Options:

- Shape and Size: Tailored designs to fit compact or complex devices.

- Coatings: Adjusted based on environmental conditions.

- Magnetization Direction: Configured for optimal performance in the intended application.

To get a quote for customized NdFeB magnets, it’s essential to provide detailed specifications such as size, coating, and application requirements. Many magnet manufacturers offer the capability to process your inquiry efficiently.

What Are the Temperature Limitations of NdFeB Magnets?

While NdFeB magnets are known for their strength, they are sensitive to high temperatures. Their magnetic properties can degrade if exposed to excessive heat.

Temperature Ranges:

- Standard NdFeB magnets operate up to 80°C.

- High-temperature grades can withstand up to 200°C.

For applications in high-temperature environments, alternative materials or special grades of NdFeB magnets should be considered.

What Are the Different Grades of Neodymium Magnets?

NdFeB magnets are categorized into grades, which indicate their magnetic strength and temperature resistance.

Common Grades:

- N35-N52: Standard grades, with N52 being the strongest.

- H, SH, UH, EH: High-temperature grades, tailored for specific industries.

Each grade is designed to balance magnetic strength and temperature resistance, ensuring compatibility with the intended application.

Where to Buy High-Quality NdFeB Magnets?

Finding reliable magnet companies or NdFeB magnet factories is essential for sourcing high-quality neodymium magnets.

Tips for Purchasing:

- Request a Quote: Reach out to manufacturers with your requirements.

- Certifications: Ensure the supplier meets industry standards for quality.

- Customization Support: Choose a supplier that offers tailored solutions.

Summary of Key Points

- NdFeB magnets are the strongest permanent magnets available today, ideal for electronics, motors, and renewable energy systems.

- Manufactured through the sintering process, they offer exceptional magnetic strength in compact sizes.

- Protective coatings such as epoxy or nickel plating enhance durability.

- Customization options allow for tailored solutions to meet specific needs.

YLSRE is a factory specializing in the production of high-performance neodymium magnets(NdFeB ) for various industries.

More

Need A Quote?

Submit your drawing

Get a free sample

We will respond within 8H of receiving your message.

Industry News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.