Customized NdFeB Magnets Assemblies

Welcome to our factory’s custom NdFeB for Automotive services, where your ideas and needs become reality.

Simply share your concepts, requirements, or design drawings, and we’ll work closely with you to produce high-quality NdFeB magnets tailored to your exact specifications and performance standards. You’ll benefit from competitive pricing, complimentary samples, and professional technical support from our dedicated team, making the customization process worry-free, safe, and cost-effective.

Our goal is to ensure that your products achieve outstanding performance with the highest level of quality and precision.

Submit Your Requirements

Our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

Of course! You are always welcome to visit us. Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. We have a friendly and professional team ready to assist you throughout your visit to make sure you have a great experience.

We are a factory! Our factory is located in the Industrial Park of the Economic Development Zone in Shehong City, Sichuan Province, China. When you order neodymium magnets from us, you work directly with our factory. This means there are no middlemen, which helps save costs, reduce risks, and ensure a safer and more efficient process for you.

Of course! To save your valuable time and ensure the sample matches your product perfectly, we kindly ask you to provide the specifications, drawings, or a sample of your product. Once we have this information, we will produce and send you the sample. We also allow mixed samples.

Our factory has a professional design team and advanced production equipment, which helps us keep costs low and provide you with high-quality magnets at very competitive prices.

First, decide the shape and size of the magnets that best suit your application. Then, visit our webpages “Customized NdFeB Magnets” and “Customized NdFeB Magnets according to Characteristics” to determine the material and grade of the magnets you need.

The next step is to go to the Quotation Request page and fill out the form with details about the magnets and the quantity you require. After clicking the “Submit” button, we will receive your request and provide you with a price quotation.

You can also contact us directly by sending your specifications and drawings.

General manager: Annie Wu

Tel: +86 18926353690

E-mail: [email protected]

It usually takes 1-3 working days. At the same time, we will assign dedicated technical staff and a business manager to your project to provide full support, including technical assistance and follow-up services.

We’re sorry, but from our experience in serving customers, we’ve learned that each customer has unique requirements for magnets, such as materials, shape, size, coating, and tolerance. Therefore, it’s challenging for us to keep all the so-called “standard size” magnets in stock.

All you need to do is provide us with your specifications, drawings, samples, or ideas, and our professional team can quickly produce magnets tailored to your custom needs.

It usually takes 2-3 weeks. If a mold needs to be made, it may take longer. For large quantity orders, such as ten thousand pieces, it may take 3-5 weeks.

Customized NdFeB Magnet Assemblies: Unleashing the Power of Precision

In the world of magnets, few materials rival the versatility and strength of Neodymium magnets (NdFeB). Known for their unmatched magnetic properties and wide-ranging applications, these rare-earth magnets have become indispensable in industries spanning electronics, automotive, medical devices, and beyond. But what happens when standard solutions won’t meet your needs? That’s when customized NdFeB magnet assemblies come into play.This article dives deep into the fascinating realm of custom magnets, explaining what they are, why they’re critical in various industries, and how they can be tailored to meet your specific requirements. Whether you’re a product designer, engineer, or business owner, this guide will help you understand how to unlock the full potential of custom neodymium magnets.

What Are NdFeB Magnets and Why Are They Special?

What Makes NdFeB Magnets Unique?

NdFeB magnets, or neodymium-iron-boron magnets, are the strongest type of permanent magnets available. These magnets have a high magnetic strength, making them ideal for applications where a powerful magnetic field is needed in a compact size. Their energy product, which measures the density of magnetic energy, is unparalleled, with grades like N35, N42, and even N55 for high-performance designs.NdFeB magnets are part of the rare-earth magnet family, which also includes samarium cobalt magnets (SmCo). While SmCo magnets offer better resistance to high temperatures, neodymium magnets are preferred for their superior strength and affordability.

Applications of NdFeB Magnets

From powering electric vehicle motors to enabling precise robotic movements, neodymium magnetic assemblies are used in countless industries. Here are just a few examples:

- Electronics: Speakers, headphones, and sensors.

- Automotive: Electric motors, braking systems, and fuel injectors.

- Medical Devices: MRI machines and surgical tools.

- Renewable Energy: Wind turbines and solar panel positioning systems.

Why Choose Customized NdFeB Magnet Assemblies?

The Need for Custom Solutions

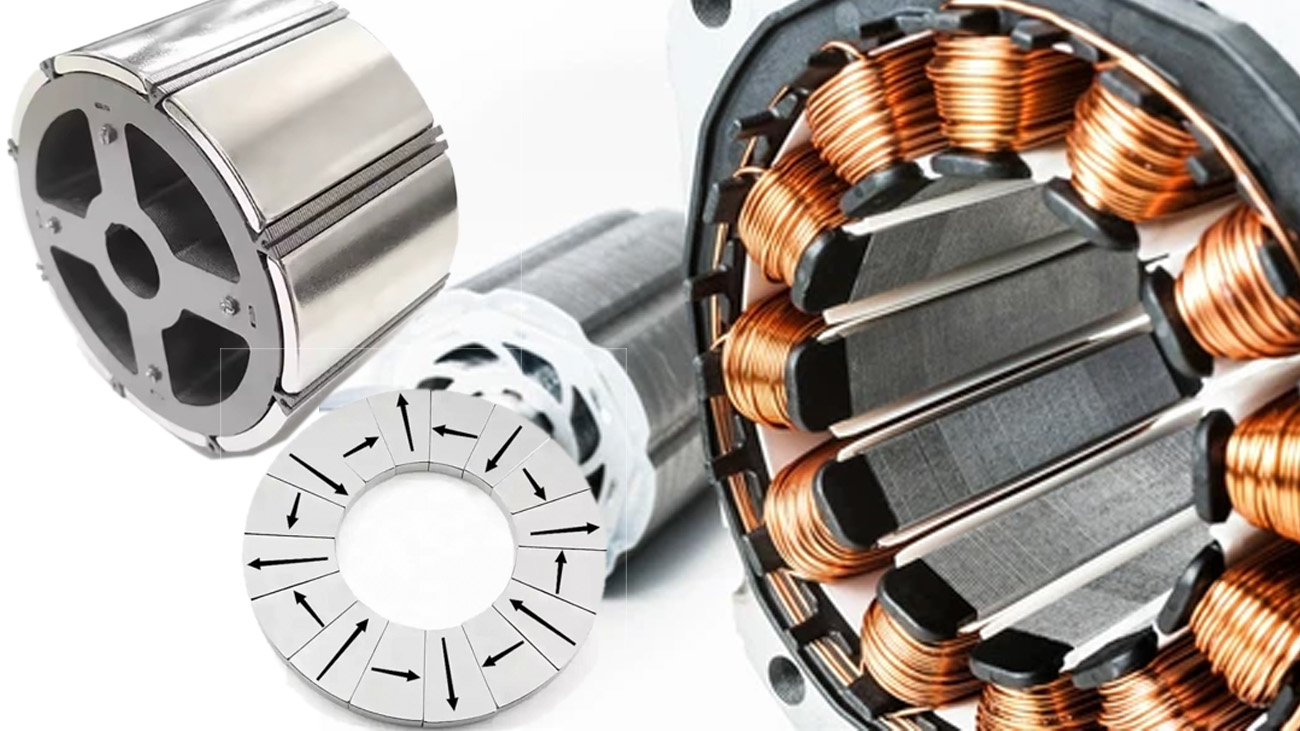

While off-the-shelf magnets work for many applications, certain projects demand custom neodymium iron boron magnets. Why? Because no two designs are the same. Factors like magnet shapes, coating, size, and magnetization directions can make or break the efficiency of your system.Custom magnetic assemblies are tailored to meet specific design and performance requirements. For instance, industries like aerospace or robotics often need magnets that can withstand high temperatures, resist corrosion, or handle specific mechanical stresses.

Advantages of Customization

- Optimized Performance: Custom magnets are designed with the exact magnetic properties required for your application.

- Improved Durability: Special coatings like nickel, epoxy, or custom plating can enhance the magnet’s resistance to wear and tear.

- Cost-Efficiency: By tailoring the magnet design, you avoid overengineering and reduce material waste.

- Flexibility in Design: Custom solutions allow for unique magnet shapes, from block magnets to intricate Halbach arrays.

How Are Custom NdFeB Magnets Made?

The Manufacturing Process

Creating custom neodymium magnets involves several precise steps:

- Material Selection: A mix of neodymium, iron, and boron is combined to create the desired alloy.

- Sintering: The material is heated and compacted into the desired shape.

- Magnetization: The finished magnet is exposed to a strong magnetic field to align its poles.

- Coating and Plating: To improve durability, magnets are coated with materials like nickel, epoxy, or cobalt.

Tailoring Magnetic Properties

Custom magnets can be tailored in terms of:

- Magnet shapes: Round, rectangular, or complex geometries.

- Magnetization directions: Axial, radial, or multi-polar.

- Coating: Enhances resistance to corrosion and mechanical wear.

- Operating temperature: Ensures optimal performance in high-temperature or extreme environments.

Key Considerations When Designing Custom Magnetic Assemblies

Magnetic Strength and Energy Product

The maximum energy product (measured in Mega Gauss Oersteds, or MGOe) determines the strength of the magnet. High-grade magnets like N42 or N55 are often chosen for demanding applications.

Resistance to External Factors

Custom magnets may require enhanced resistance to factors like:

- Corrosion: Especially important in marine or chemical environments.

- Heat: Certain designs, like samarium cobalt or specialized coatings, ensure magnets perform in extreme operating temperatures.

Size and Shape

Custom designs often involve intricate or non-standard magnet shapes, which must be carefully engineered to fit seamlessly into complex systems.

Choosing the Right Coating for Your Custom NdFeB Magnet

Types of Coatings

Coating is crucial to protect the magnet’s surface and enhance its lifespan. Popular options include:

- Nickel: Offers excellent corrosion resistance.

- Epoxy: Provides a durable, moisture-resistant finish.

- Cobalt or Plating: Ideal for extreme environments or high-temperature applications.

How Coating Affects Performance

The right coating not only protects the magnet but can also enhance its magnetic properties by preventing demagnetization or surface damage.

Common Applications of Custom Magnetic Assemblies

- Automotive Industry

- Electric motors

- Advanced driver-assistance systems (ADAS)

- Medical Equipment

- Precision surgical tools

- Diagnostic imaging systems

- Renewable Energy

- Wind turbine generators

- Solar tracking systems

- Consumer Electronics

- Compact speakers

- Wearable devices

FAQs About Custom NdFeB Magnets

What is the lifespan of a custom NdFeB magnet?

With proper coating and environmental protection, neodymium magnets can last decades without significant loss of strength.

Can custom magnets withstand extreme temperatures?

Yes! By selecting the appropriate materials and plating, magnets can operate in temperatures exceeding 200°C. Samarium cobalt magnets are another excellent option for high-temperature applications.

How do I request a custom magnet quote?

When you contact us, share details like required magnet shapes, magnetization directions, and environmental conditions to receive a tailored solution.

The Versatility of Rare-Earth Magnets

Custom rare-earth magnets, especially neodymium magnetic assemblies, offer unparalleled strength and adaptability. Their ability to be tailored for specific applications makes them indispensable in modern engineering and manufacturing.

Why Work with a Leading Manufacturer?

Choosing a leading manufacturer ensures:

- Access to advanced manufacturing capabilities.

- Expertise in designing magnetic assemblies to meet unique needs.

- High-quality materials and strict quality assurance.

Whether you need standard magnets or fully customized solutions, working with an experienced team ensures your project’s success.

Conclusion: Unlocking the Potential of Custom Magnetic Assemblies

To summarize, custom NdFeB magnet assemblies provide:

- Tailored designs for specific applications.

- Enhanced performance through precise engineering.

- Durable and long-lasting solutions with custom coating options.

If you’re ready to explore the power of custom neodymium magnets, don’t hesitate to contact us today. Let us help you turn your ideas into reality with cutting-edge magnetic solutions.

Key Takeaways

- NdFeB magnets are the strongest type of permanent magnet, offering incredible versatility.

- Custom solutions optimize performance, durability, and cost-efficiency for specific projects.

- Proper design considers magnet shapes, magnetization, and environmental factors like corrosion and temperature.

- Work with a trusted magnets manufacturer to ensure high-quality results.

For more information or to Request a Quote, Contact Us today!

YLSRE is a factory specializing in the production of high-performance neodymium magnets(NdFeB ) for various industries.

More

Need A Quote?

Submit your drawing

Get a free sample

We will respond within 8H of receiving your message.

Industry News

US Department of Defense Allocates $5.1 Million to Recover Rare Earths from E-Waste

On January 17, 2025, the US Department of Defense announced a $5.1 million allocation to Rare Resource Recycling Inc. under the Defense Production Act.

China Revises and Implements the “Regulations for Outward Direct Investment Statistics,” Including Rare Earth Oxides

It is reported that on January 1, 2025, the Ministry of Commerce, the National Bureau of Statistics, and the State Administration of Foreign Exchange officially implemented the revised “Regulations for Outward Direct Investment Statistics.”

Canada Rare Earth Acquires Majority Stake in Laos Rare Earth Refinery

According to Magnet Materials News, on January 9, 2025, Canada Rare Earth Corp. announced plans to acquire a 70% stake in a rare earth refinery in Laos. This acquisition aims to enhance supply security and economic benefits.